Aerogels are ultralight materials in which the liquid component of a gel has been replaced with a gas. Polymer aerogels can be used, e.g., as superinsulators, solvent absorbents, or catalyst supports. They can also act as shape‐memory materials: Aerogels made from hydrophobic, semicrystalline polymers, for example, can combine high stiffness with excellent flexibility and are suitable for this type of application.

Damien Montarnal, University of Lyon, France, and colleagues have combined chemical crosslinking with high crystallinity to make high‐density polyethylene (HDPE) aerogels that have better mechanical properties than aerogels with only physical crosslinks. The team used highly crystalline HDPE segments functionalized with vinyl groups to optimize the crystallinity of the final material. These polymer segments were connected via a platinum‐catalyzed hydrosilylation reaction. Aerogels were then obtained by freeze-drying the resulting polymer gels.

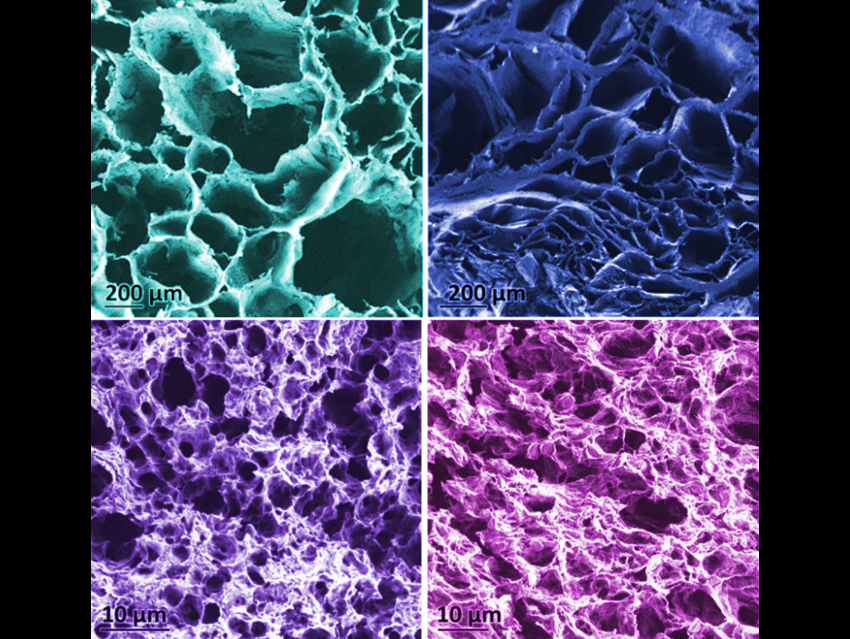

The HDPE aerogels (microscopic structure pictured) have high crystallinities, are mechanically resilient, and can recover from deformations. This could make them useful as shape‐memory materials.

- Polyethylene Aerogels with Combined Physical and Chemical Crosslinking: Improved Mechanical Resilience and Shape-Memory Properties,

Douriya Khedaioui, Christophe Boisson, Franck D’Agosto, Damien Montarnal,

Angew. Chem. Int. Ed. 2019.

https://doi.org/10.1002/anie.201908257

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)