Gold leaf is generally used for decorative purposes. However, if its mechanical strength and flexibility were improved, it could be useful for, e.g., wearable electronic devices due to its electrical conductivity and biocompatibility.

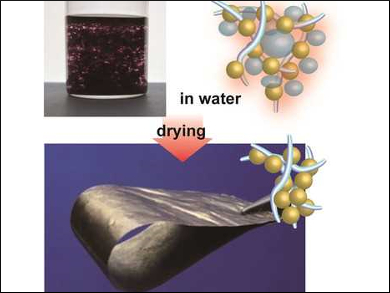

Hiroshi Shiigi, Osaka Prefecture University, Japan, and colleagues have developed a process for the integration of gold nanoparticles (AuNPs) and cellulose nanofibers (CNFs) to create an organic/inorganic hybrid film. CNFs were mixed with citrate-coated AuNPs in an aqueous solution and the precipitate was dried to give the desired hybrid material. The AuNPs are bound to the CNFs, while the aggregation of the nanoparticles is prevented by electrostatic repulsion.

This “smart gold leaf” has good mechanical strength, flexibility, self-healing ability, and electrical resistivity, with a relatively small gold content (13 vol.%). The smart gold leaf also has excellent chemical and temperature resistances. Self-assembly allows the formation of the material on three-dimensional micrometer-sized substrates, where a uniform flexible metallic layer cannot be created using conventional techniques. The material could be used in, e.g., coatings, smart papers, or wearable devices.

- Smart Golden Leaves Fabricated by Integrating Au Nanoparticles and Cellulose Nanofibers,

Hiroshi Shiigi, Tomohiro Tomiyama, Maki Saito, Kengo Ishiki, Dung Q. Nguyen, Tatsuro Endo, Yojiro Yamamoto, Xueling Shan, Zhidong Chen, Tomoaki Nishino, Hidenobu Nakao, Tsutomu Nagaoka,

ChemNanoMat 2019.

https://doi.org/10.1002/cnma.201800643

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)