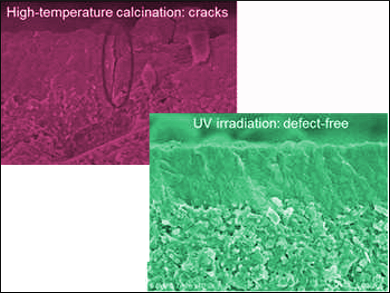

Zeolite membranes are useful, e.g, for gas separations. One problem for the reliable fabrication of zeolite membranes is the fact that organic templating molecules embedded in the zeolite must be removed by high-temperature calcination. This creates cracks (pictured in red) and plugged pores, leading to poor performance. This is especially problematic for small-pore zeolites.

Sankar Nair, Georgia Institute of Technology, Atlanta, USA, and colleagues have developed a UV treatment that can remove zeolite templates at near-ambient temperature, providing an alternative to harsh calcination processes. The team produced high‐performance hollow fiber membranes of the small‐pore (0.38 nm) zeolite SSZ‐13. UV irradiation caused the complete removal of the bulky template compound trimethyladamantylammonium hydroxide from the pores, without introducing defects (pictured in green).

The UV-treated membranes have a much higher hydrogen/propane selectivity (800) and a significantly improved CO2/methane selectivity (110) compared with calcined membranes (< 5). According to the researchers, the developed low‐temperature UV activation could be a significant step towards reliable, scalable, and low‐cost fabrication processes for zeolite membranes.

- Highly Selective SSZ-13 Zeolite Hollow Fiber Membranes by Ultraviolet Activation at Near-Ambient Temperature,

Shaowei Yang, Yeon Hye Kwon, Dong-Yeun Koh, Byunghyun Min, Yujun Liu, Sankar Nair,

ChemNanoMat 2018.

https://doi.org/10.1002/cnma.201800272