Biomass as a renewable energy source is increasingly used to provide heat, hot water, and electricity. Regular gasification, however, has a fluctuating output depending on the input biomass and process parameters, while unburned carbon is discharged with the exhaust gas. Therefore, robust and cost-effective systems are required to ensure a cleaner and more efficient biomass combustion process.

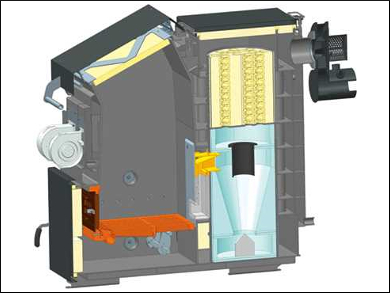

Mohammad Aleysa and colleagues, Fraunhofer Institute for Building Physics, Stuttgart, Germany, have developed an innovative low-emission combustion system (pictured). An intelligently controlled three‐fan combustion air supply and exhaust gas system stabilizes the operation, independent of the boiler design and fuel used. A cyclone combustion chamber intensifies the mixing of oxygen with the fuel gas, leading to more efficient gasification. Additionally, due to its unique structure, it doubles as a dust separator. A packed bed at the end, made of special ceramics, functions as a thermal reactor to treat even hard-to-oxidize components, further reducing unwanted emissions.

Experiments with different biomasses, such as beech plywood, spruce wood, or mixed woodchips, have shown that the system is highly efficient and results in lower exhaust emissions. It is a cost-effective combustion system for different biogenic fuels. According to the researchers, a minimum increase of the boiler efficiency of 15 % in practice, with corresponding fuel and CO2 savings, is achieved.

- Innovative Combustion System for Economic and Ecological Thermal Utilization of Solid Fuel in Heating Boilers,

Mohammad Aleysa, Souha Meriee, Niro Akbary, Martin Ecker,

Chem. Eng. Technol. 2018.

https://doi.org/10.1002/ceat.201800118The article is part of the Chemical Engineering & Technology Special Issue on Bioenergy.