The production, transport, and consumption of oil and petroleum products have increased steadily for some time, which increases the potential for marine oil spills and their disastrous environmental consequences. The most common method for cleaning up oil spills is containment and skimming, using sorbents or sponges to remove the oil from the water surface. There are porous substrates with superhydrophobic properties that selectively absorb oil, but these sponge-like materials are generally not mechanically stable and cannot be recycled.

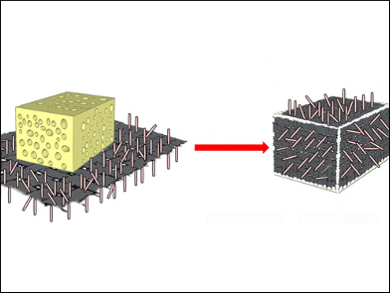

Maryam Khosravi and Saeid Azizian, Bu-Ali Sina University, Hamedan, Iran, have prepared a new oil spill collector consisting of a piece of polyurethane foam wrapped in a carbon cloth that is loaded with ZnO microrods and modified with stearic acid. Owing to the superhydrophobic and superoleophilic properties of the modified carbon cloth, the oil collector can absorb a variety of oils and organic solvents in amounts of up to 70 times its own weight. The sorbed oils can be pressed out of the collector and the collector can be recycled up to 100 times.

The carbon cloth was also used in a filtering device under vacuum for the continuous removal of oil floating on water. Remarkably, the oil/water separation was also efficient for a vigorously stirred mixture, conditions that simulate the real-life conditions of an oil spill.

- Fabrication of an Oil Spill Collector Package by Using Polyurethane Foam Wrapped with Superhydrophobic ZnO Microrods/Carbon Cloth,

Maryam Khosravi, Saeid Azizian,

ChemPlusChem 2018, 83, 455–462.

https://doi.org/10.1002/cplu.201800145