Inorganic–organic hybrid materials are useful for a variety of applications. Mesoporous materials are especially attractive due to their high surface area, large pore volume, and tunable pore size. Nevertheless, high cost and limited options for hybridizing molecules, which are usually organosilanes, remain as challenges. Recently, phosphonic acids have been used for these nanocomposites, however, their acidic nature tends to result in rapid hydrolysis of the inorganic precursor. Hence, only a few selected metal phosphonates with ordered mesoporous structure have been prepared so far via template-free or surfactant-assisted self-assembly.

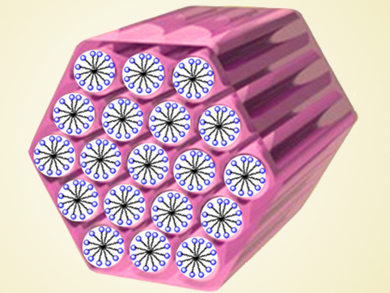

Malay Pramanik, National Institute for Materials Science (NIMS), Ibaraki, Japan, Jung Ho Kim, NIMS and University of Wollongong, North Wollongong, Australia, Yusuke Yamauchi, NIMS, University of Wollongong and King Saud University, Riyadh, Saudi Arabia, and colleagues have fabricated mesoporous vanadium phosphonates (MVP) using a one-pot approach with cetyltrimethylammonium bromide (CTAB) as the soft template, which is later removed, and nitrilotris(methylene)triphosphonic acid as the organophosphorus coupling molecule. A control material without CTAB (VP-B) was also synthesized.

The team characterized the materials using a wide array of X-ray and electron microscopy techniques, showing that the MVPs have 2D hexagonal and cubic phases, with a pore-to-pore distance of 4.23 nm. However, the pore walls are rather amorphous, and the components do not form a highly-ordered crystalline arrangement. In contrast, VP-B did not show any mesoporous morphology or highly ordered structures. The MVPs showed excellent coloumbic efficiency and high capacity retention compared to VP-B or graphite anodes, which makes them promising as alternative anode materials for lithium-ion batteries.

- Highly Ordered Mesostructured Vanadium Phosphonate toward Electrode Materials for Lithium-Ion Batteries,

Peng Mei, Malay Pramanik, Jaewoo Lee, Yusuke Ide, Zeid Abdullah Alothman, Jung Ho Kim, Yusuke Yamauchi,

Chem. Eur. J. 2017, 23, 4344–4352.

DOI: 10.1002/chem.201604159