Plastics have become indispensable in our daily lives. However, the uncontrolled disposal of plastic waste has created major environmental problems. To better manage this waste stream, cost-efficient upcycling strategies are needed that use plastic waste as a raw material to prepare new value-added materials.

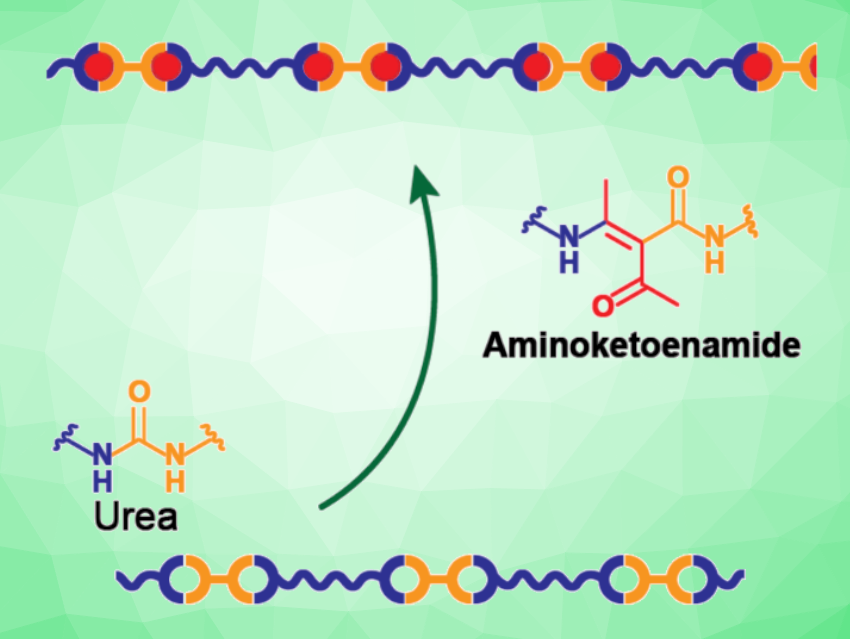

Zixing Shi, Shanghai Jiao Tong University, China, Christoph Weder and José Augusto Berrocal, University of Fribourg, Switzerland, and colleagues have investigated how polyureas can be de-crosslinked, de-polymerized, and transformed into dynamic covalent poly(aminoketoenamide) networks. The upcycling process occurs via two steps: A reaction between ureas and acetylacetone—a cheap and readily available chemical—produces vinylogous amides as synthetic intermediates. This is followed by the conversion of the amides into aminoketoenamides by a second reaction with diphenyl diisocyanate.

The polyaminoketoenamides prepared with this method possess better mechanical properties than the starting polyureas. Moreover, they can be healed, reprocessed, and recycled several times, which is not possible with the original polyureas. According to the researchers, this method could stimulate the development of analogues to urea-based plastics, which currently have a market of ca. USD 1.1 billion.

- Chemical Upcycling of Conventional Polyureas into Dynamic Covalent Poly(aminoketoenamide)s,

Youwei Ma, Xuesong Jiang, Jie Yin, Christoph Weder, José Berrocal, Zixing Shi,

Angew. Chem. Int. Ed. 2022.

https://doi.org/10.1002/anie.202212870

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)