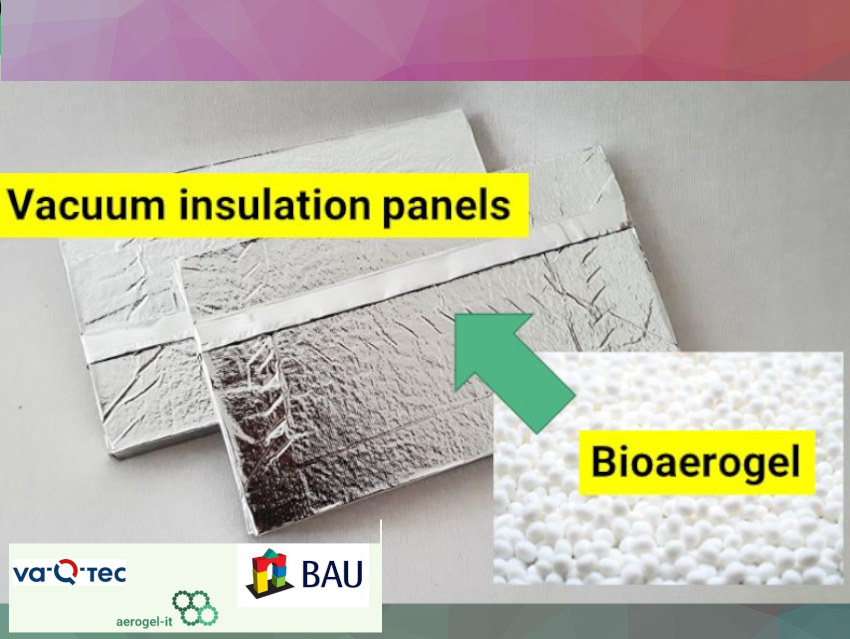

Aerogel-it and va-Q-tec Thermal Solutions GmbH unveil an advancement in thermal insulation: vacuum insulation panels (VIPs) with a bioaerogel core. This material combines the high performance of traditional fumed silica VIPs with lightweight, bio-based sustainability.

After three years of collaboration, the teams have developed prototypes of these bioaerogel VIPs, suitable for applications in construction, logistics, and cooling appliances. Aerogels are so-called super insulation materials that are extremely light and consist almost entirely of microscopic pores. As a result, they transport heat very poorly. Aerogel insulation, therefore, prevents heat loss much more than conventional material. Aerogels can be made from various substances, but, until now, they have been based almost exclusively on fossil or energy-intensively extracted raw materials, such as silicate minerals. In addition, aerogels have always been expensive due to their complex production.

Dr. Marc Fricke, CEO & cofounder of aerogel-it told ChemistryViews that “the most challenging part was to develop a bio-based aerogel which shows similar high-performance as vacuum insulation panel at lower density like the state-of-the-art fumed silica.” Their bioaerogel is made of cellulose, the most abundant biopolymer on earth and main part of wood. The aerogel insulation is thinner and lighter than conventional insulation, so it creates more space in buildings. Furthermore, the bio-based insulation material can be recycled or even reused.

- aerogel-it GmbH, Osnabrück, Germany

- va-Q-tec Thermal Solutions GmbH, Würzburg, Germany

Also of Interest

M. Fricke and R. Subrahmanyam on their 100 % bio-based insulating lignin aerogel and their BASF spin-off