Flow chemistry can be useful for the production of fine chemicals such as pharmaceuticals, nutraceuticals, and food-related compounds at the industrial level. At the same time, biocatalytic approaches are considered key techniques for a greener way to operate in chemistry. Flow biocatalysis can combine the advantaged of advantages of flow chemistry, such as better parameter control, higher mass and heat transfer, and modularity, with the mild reaction conditions and the selectivity offered by biocatalysts.

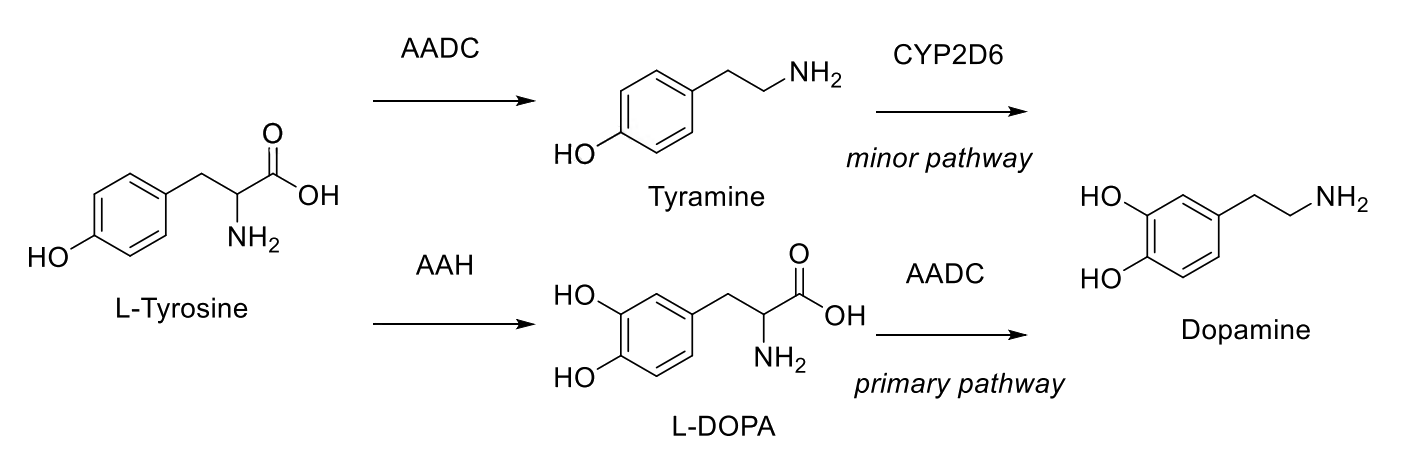

Martina L. Contente, University of Milan, Italy, and colleagues have developed a multi-enzymatic platform for the biocatalytic preparation of dopamine (pictured above) in a continuous mode. The team mimicked the natural metabolism for the synthesis of dopamine, which proceeds via two different pathways (pictured below, AADC = L-aminoacid decarboxylase, AAH = amino acid hydroxylase, CYP2D6 = cytochrome 2D6).

The team used sequentially connecting bioreactors filled with enzymes immobilized onto agarose beads. They used a decarboxylase from Bacillus pumilis and a tyrosinase from Agaricus bisporus, which were combined to mimic the in-vivo synthesis. Dopamine was obtained in high yields (85 %) and short residence times (45 min).

According to the researchers, this flow set-up designed for the synthesis of dopamine is just one example of how flow biocatalysis can provide a robust, reliable, efficient, and versatile technique to address industrial needs.

- Mimicking natural metabolisms: cell‐free flow preparation of dopamine,

Silvia Donzella, Agostina Colacicco, Luca Nespoli, Martina Letizia Contente,

ChemBioChem 2022.

https://doi.org/10.1002/cbic.202200462