Adhesives are important in many industries, e.g., in the production of plywood. However, they are often made from non-sustainable resources. In addition, formaldehyde-based resins, which are often used as adhesives in wood-based products, can release harmful formaldehyde over time. Nontoxic adhesives made from renewable resources would be useful alternatives, but their water resistance and bonding strength still need improvement.

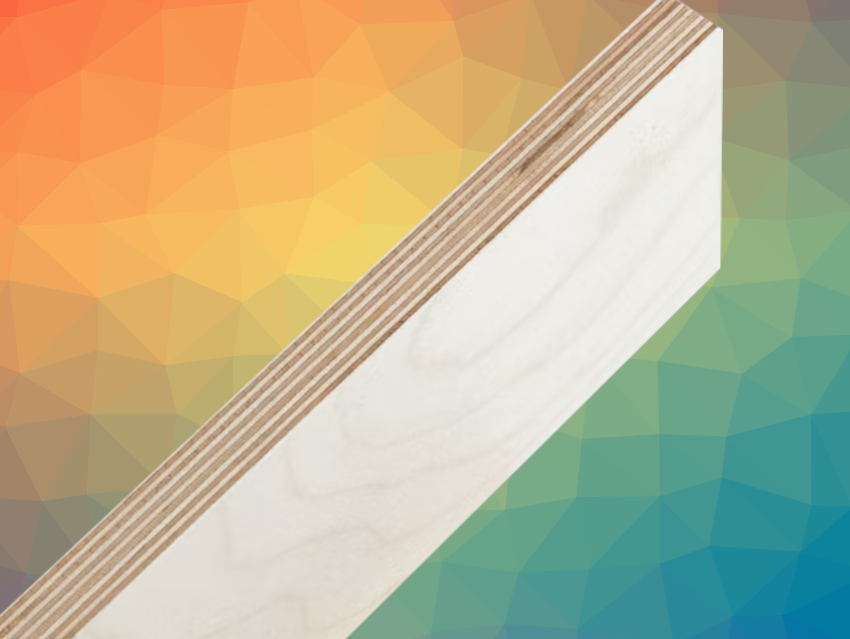

Hong Lei, Southwest Forestry University, Kunming, China, and colleagues have developed a fully biomass-based citric acid/glucose adhesive with properties that can be tuned by changing the reaction time and the molar ratio of the two components. The team heated aqueous solutions of glucose with varying amounts of added citric acid to 110 °C to obtain the desired adhesives via an esterification reaction. The resulting adhesives were applied onto thin layers of poplar, which were pressed at 200 °C to create three-layer plywood.

The team found that the higher the molar ratio of citric acid to glucose, the higher the shear strength and water resistance of the plywood. The researchers attribute this to an increase in the number of ester links between the −CO2H groups of citric acid and −OH groups on the wood surfaces. For molar ratios of more than 0.6 and a reaction time of 1 h, the shear strength results were found to satisfy the standard requirements for plywood. According to the researchers, citric acid/glucose adhesives are promising for applications in the wood-products industry.

- Fully Biobased Adhesive from Glucose and Citric Acid for Plywood with High Performance,

Chunyin Li, Hong Lei, Zhigang Wu, Xuedong Xi, Guanben Du, Antonio Pizzi,

ACS Appl. Mater. Interfaces 2022.

https://doi.org/10.1021/acsami.2c02859

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)