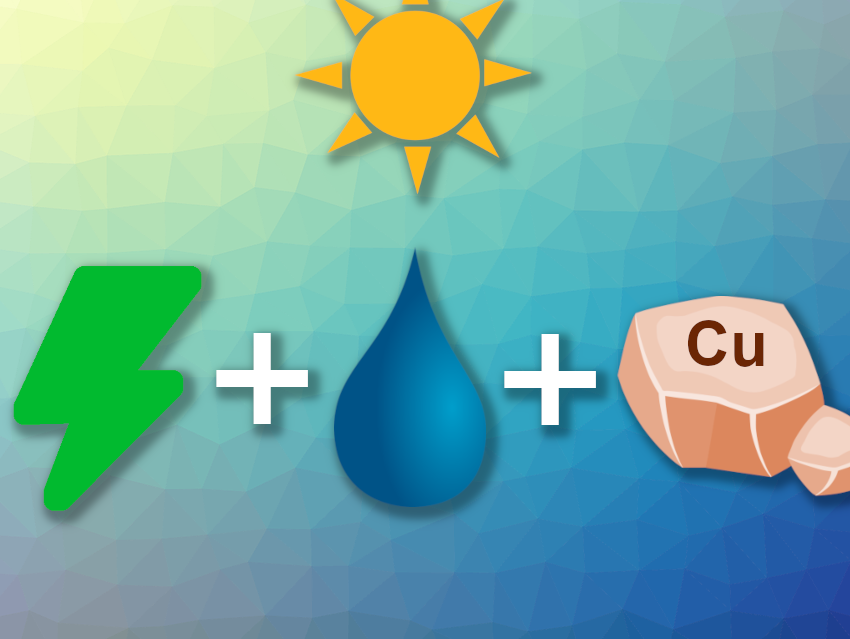

With an ever-growing global population, having enough power and water to go round is becoming an increasingly important issue. Chi Wang, Mingxin Huo, Northeast Normal University, Changchun, China, and colleagues have developed a system that solves both these problems while regenerating metals found in wastewater—all using renewable solar energy.

A Solar-Driven Thermal-Electric Cogeneration System—or “STECS”

The researchers developed a system dubbed STECS (solar-driven thermal-electric cogeneration system). Their electrolysis-based system purifies wastewater containing heavy metals, with the metal accumulating at the cathode for recovery and recycling.

Systems like this are already used to regenerate metals and purify water, but the team’s concept goes much further thanks to their anode being a photoanode powered by sunlight alone. This not only enables electricity generation, but at the same time generates heat, causing water to evaporate and recondense as purified water which can be reused. In a single unit, therefore, polluted water can be purified, energy can be produced, and water can be cleaned.

Key Photoanode Materials

The key to the success of the team’s STECS system is the photoanode, made of intermingled fibers containing a semiconductor material, titanium dioxide (TiO2), along with carbon fluoride (CF) for absorbing sunlight. The team produced this material using a solvothermal method, heating a mixture of the constituents for 4 h at 180 °C, followed by annealing the composite material at 500 °C for another 4 h.

The resulting composite material generates useful current densities when irradiated with simulated sunlight, and using Na2EDTA (EDTA = ethylenediaminetetraacetic acid) as the electrolyte further increases the available power produced.

The photoanode absorbs solar radiation thanks to the CF present in the material. When the CF absorbs this radiation, the interface between the material and the water heats up, causing water to evaporate and recondense in a purified form. With greater light intensity, more water evaporates.

The System as a Whole

In summary, the system operates by sunlight shining on the photoanode. At this point, the CF in the composite material absorbs sunlight and heats up, causing evaporation of water at the interface between material and wastewater. A suitably-designed collector allows this water to recondense.

At the same time, the TiO2 in the composite material is excited by the sunlight, releasing electrons and producing “holes” (i.e., gaps where an electron would usually sit), which ultimately leads to reactive radicals being formed. These oxidize the metal complexes present in the wastewater, generating metal ions which are attracted to the platinum cathode. There, they are reduced, ready to be recovered as metal.

All the while, the electrons produced by the excited TiO2 are also flowing, producing recoverable energy. The team tested the system using simulated copper-laden wastewater and found that it achieved a high level of efficiency.

Because STECS runs solely on solar power, the team propose that the system could be applied in the future as a cost-effective and sustainable way to recover metals, purify wastewater, and provide a source of energy at the same time.

- A Solar-Driven System Enabling Simultaneous Water Recovery, Heavy Metal Recycling, and Electricity Generation,

Linwei Hou, Kaichen Sun, Chi Wang, Xianze Wang, Zhi Geng, Yumeng Zhao, Mingxin Huo, Meng Sun,

ACS EST Eng. 2024.

https://doi.org/10.1021/acsestengg.4c00185