Modern integrated microelectronic devices are often poorly repairable and difficult to recycle. “Debondable” adhesives could play a key role in the transition to a circular economy with sustainable resources, less waste, and intelligent repair and recycling strategies. Kannan Balasubramanian, Hans G. Börner, Humboldt University Berlin, Germany, and colleagues have developed a method for making adhesives that can be deactivated “on command”.

Mussel-Inspired Adhesives

The team’s inspiration came from the masters of underwater adhesion: mussels. Mussel-inspired adhesives have been developed before. The new versions developed by the researchers are based on thiol-catechol polyaddition, which forms polymers with adhesive thiol-catechol connectivities (TCC, thiol-substituted six-membered aromatic rings with two neighboring OH groups which are responsible for the strong adhesive properties).

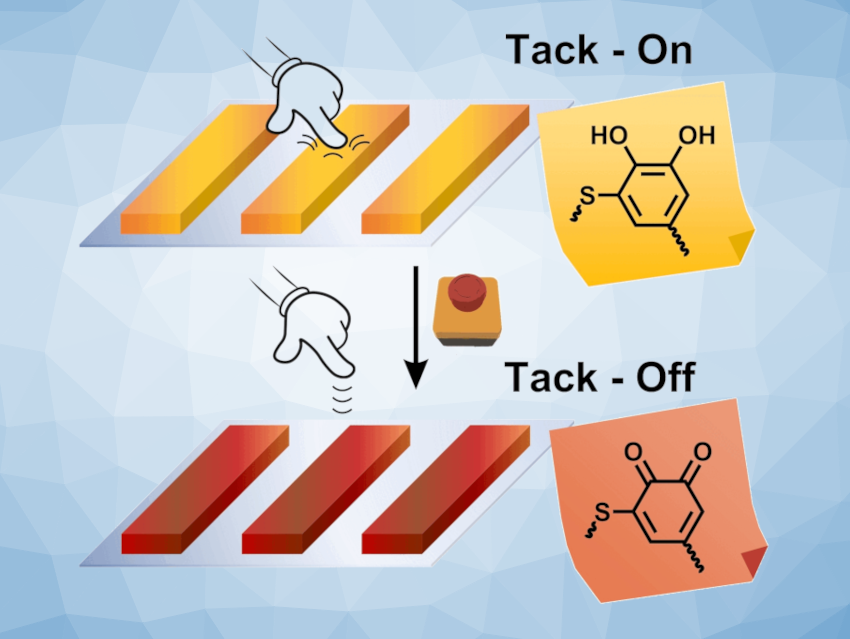

The trick is that when the catechol groups in the adhesive polymers are oxidized to quinones (pictured), the strength of adhesion decreases dramatically.

Peptidic Biscatechol vs. a Fossil-Based Analogue

Changing the basic framework of the monomers allows for control over the properties of the polymers. The team produced two different types of TCC adhesives with strong adhesion and shear strength.

Biobased, peptidic biscatechol precursors of DiDOPA, which is similarly found in mussels, were compared with a fossil-based analog that was made using bisquinone A. Both adhesives also function underwater and are insensitive to atmospheric oxygen and weak oxidizing agents. However, they lose their stickiness through oxidation with the strongly oxidizing sodium periodate (NaIO4), so that the adhesive residues can be easily peeled or wiped off the substrate in one piece.

More Efficient Debonding

While the oxidation of the fossil adhesive inactivates the catechols, but at the same time makes the adhesive more hydrophobic, the biobased type shows the deactivation without becoming dramatically more hydrophobic due to a variety of other peptide functionalities. Börner explains: “The multifunctionality is typical of biomaterials, in which often only the key functionalities are switched off and not much else changes in the material. This circumstance enables a dramatically more efficient de-adhesion mechanism, which reduces the adhesive strength of the bio-based type by 99 %.”

The reason for the poorer deactivation (60 %) of the fossil-based adhesive lies in the compensation through hydrophobic contacts, as hydrophobic polymers are also very good adhesives. In the longer term, the team is working on replacing chemical oxidation with direct electrochemical oxidation, which could be interesting for the repair of cell phones, for example.

- Redox‐Triggered Debonding of Mussel‐Inspired Pressure Sensitive Adhesives: Improving Efficiency Through Functional Design,

Tilmann J. Neubert, Keven Walter, Carolin Schröter, Victoria Guglielmotti, Karsten Hinrichs, Stefan Reinicke, Andreas Taden, Kannan Balasubramanian, Hans G. Börner,

Angew. Chem. Int. Ed. 2024.

https://doi.org/10.1002/anie.202408441