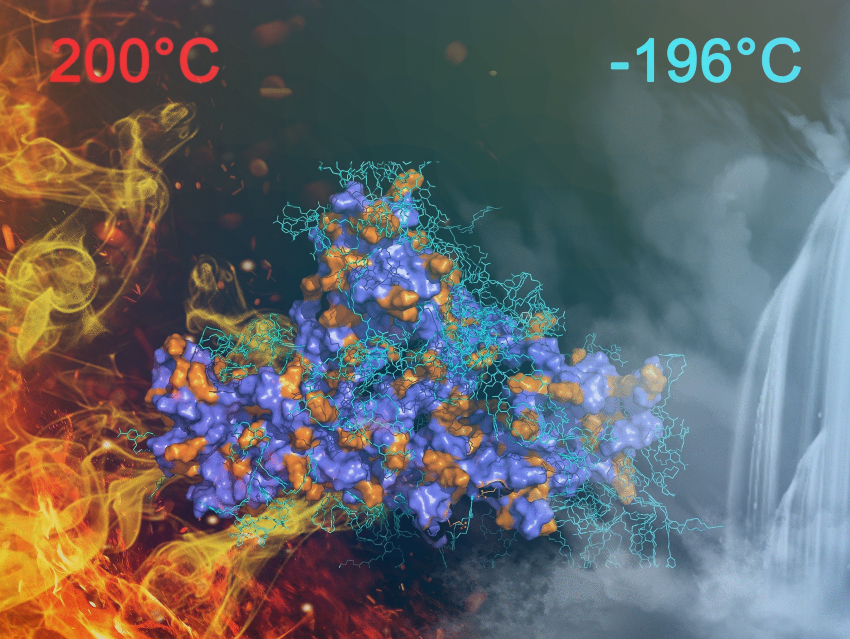

A supramolecular adhesive that is recyclable and has outstanding gluing properties across a wide range of temperatures, from liquid nitrogen (−196 °C) up to oven-hot temperatures (200 °C), has been developed. As Yawei Liu, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Fangfu Ye, Beijing National Laboratory for Condensed Matter Physics, Chinese Academy of Sciences, and University of the Chinese Academy of Sciences, Wenzhou, Jing Sun, Ulm University, Germany, Kai Liu, Changchun Institute of Applied Chemistry, University of Science and Technology of China, Hefei, and Tsinghua University, Beijing, China, and colleagues report, the adhesive gets its efficiency from an exceptionally tight interlocking of the molecular components during curing.

Supramolecular Glues

Unlike standard adhesives, supramolecular adhesives do not create adhesion by the molecular components crosslinking with one another. Instead, they form a tight-knit self-assembly during curing, like puzzle pieces fitting together.

Researchers are interested in such supramolecular systems because they offer sustainability and customizability and, in principle, the individual starting materials can be recovered again and their chemical behavior can be tailored. However, to date, the performance of such glues has been decent at best, not to mention highly dependent on environmental conditions.

Crown-Ether-Protein Adhesive

The new supramolecular glue consists of two components, one of which is a small protein that is synthesized in bacteria modified for the purpose. The other component is a crown ether—a ring-shaped molecule that can wrap snugly around another molecule, much like a crown sitting on a queen’s head.

The researchers observed this snug interaction between the molecules in their adhesive system. By adding the crown ether and the protein together and heating the solution for curing, the crown ether became anchored to the surface of the protein. The team noted that the protein and crown ether were so tightly bound to each other by their opposing charges and other molecular interactions that they formed a new, interlocking structure, which “welded” the proteins together.

High Adhesion Performance

The result is an extraordinarily strong adhesive effect. Steel plates glued together withstood high shear forces at room temperature, in liquid nitrogen, and at 200 °C. The adhesive worked for different materials, and underwater as well. Such a broad spectrum of working conditions is seldom achieved, even with specialist adhesives, and is certainly a first for supramolecular adhesives. Promisingly, the interlocking components could be broken apart and recycled again, and the reused adhesive lost virtually none of its power.

The researchers believe that one reason for this exceptional adhesive effect, particularly at low temperatures, is a result of the specific supramolecular interactions at play. In particular, the tight interlocking of the components drove water out of the protein. This meant that no ice crystals were able to form when frozen—which in many conventional glues would lead to premature cracking.

The researchers suggest that this new adhesive could be applied to the manufacture of special parts that will be subject to greatly fluctuating conditions during use; for example, the wide temperature ranges to which spacecraft are exposed.

- Molecular Engineered Crown‐Ether‐Protein with Strong Adhesion over a Wide Temperature Range from −196 to 200 °C,

Kelu Zhao, Yawei Liu, Yubin Ren, Bo Li, Jingjing Li, Fan Wang, Chao Ma, Fangfu Ye, Jing Sun, Hongjie Zhang, Kai Liu,

Angew. Chem. Int. Ed. 2022.

https://doi.org/10.1002/anie.202207425