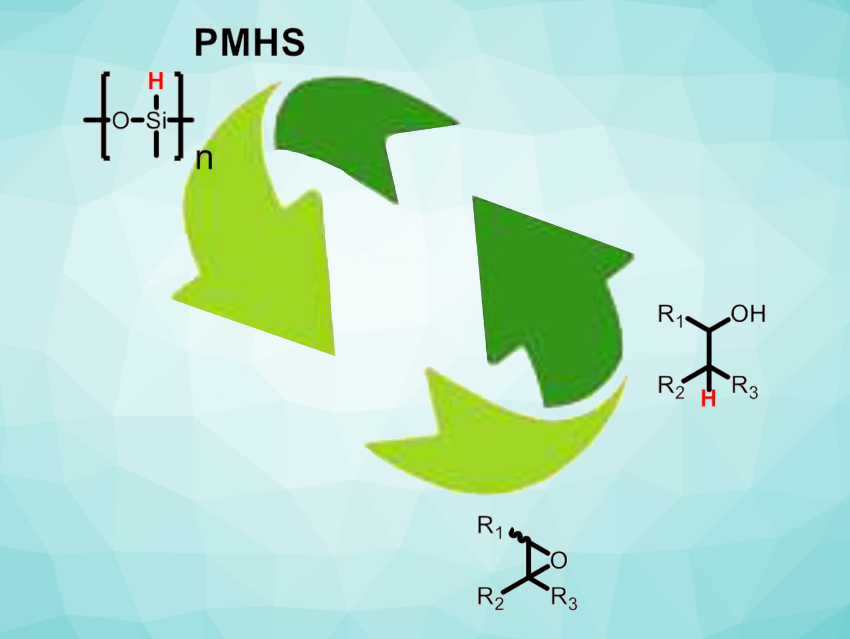

Efficient waste management is one of the key challenges in creating a more sustainable economy. Waste prevention and the recovery and reuse of byproducts can be important tools for reducing the waste created by industrial processes. Andreas Gansäuer, University of Bonn, Germany, and colleagues have found added value in a polymeric waste product of the silicone industry, polymethylhydrosiloxane (PMHS). The team used this compound in a titanocene-catalyzed epoxide hydrosilylation reaction.

Catalytic epoxide hydrosilylations (followed by hydrolysis) are useful for the preparation of alcohols. They can be part of a reaction sequence for the formal anti-Markovnikov addition of water to olefins. The reaction can be titanocene-catalyzed and involves an intramolecular hydrogen atom transfer (HAT). It is of interest for industrial use because epoxides are easily accessible and titanium is earth-abundant. However, so far, phenyl- or phenylmethylsilane (PhSiH3 or PhSi(CH3)H2) have been used as silane reagents in similar reactions. These reagents are ca. 40–90 times more expensive than PMHS.

Using PHMS as a reductant, the team converted a range of benzylic or alkyl-substituted epoxides into the desired alcohols using Cp2TiCl2 as the catalyst in the presence of BnMgBr and substoichiometric amounts of PhSiH3, with a mixture of tetrahydrofuran (THF) and 1,4-dioxane as the solvent. The reaction proceeds at room temperature. Due to the low cost of the reagents, multigram-scale reactions are easily feasible. In a representative example, the desired product was obtained in 89 % yield in a reaction on a five-gram scale.

- Polymethylhydrosiloxane (PMHS) as sustainable reductant in the titanocene catalyzed epoxide hydrosilylation,

Jonathan Heinrich Schacht, Shangze Wu, Sven Klare, Sebastian Höthker, Niklas Schmickler, Andreas Gansäuer,

ChemCatChem 2022.

https://doi.org/10.1002/cctc.202200852