Bacteria are sometimes used for therapeutic purposes, such as bioimaging or targeted drug delivery. In these cases, they need to be encapsulated to protect them from the body’s natural digestion and immune responses and to ensure they reach their intended site. Encapsulation, however, usually means embedding multiple bacteria in a hydrogel or locking all of them up together in a polymer capsule.

Single-Cell Encapsulation

Andrea Belluati, Nico Bruns, Technical University of Darmstadt, Germany, University of Strathclyde, Glasgow, UK, and colleagues have refined this process and introduced a technique that allows Escherichia coli cells to be coated individually. Like a jacket pulled over each cell, a thin polymer layer covering each cell protects the bacteria from harsh environments. In addition, it allows surface functionalization without a need for genetic engineering [1].

To enable the coating of bacteria, the researchers adapted a phospholipid-based camouflaging strategy for nanoparticles and bacteria. When they are co-extruded with red blood cell membranes and passed through a porous membrane, E. coli bacteria are wrapped in a foreign membrane shell. This keeps the bacteria hidden, so they can be used in therapeutic applications without alerting the body to their presence [2]. However, natural phospholipids have shortcomings such as instability and immunogenicity, so the team turned to artificial polymers as phospholipid mimics.

Block Copolymer Coating

The team chose a polymer type often used in drug delivery, poloxamers. These block copolymers are composed of poly(ethylene glycol) (PEG) and poly(propylene glycol) (PPG) blocks, and their amphiphilic nature means they are widely used as surfactants. In addition, they assemble to form vesicles, as phospholipids do, and are biologically safe. The type of triblock poloxamer selected by the researchers, Pluronic L-121 (PL121), contains two short PEG blocks of five units flanking a longer PPG block of 62 units.

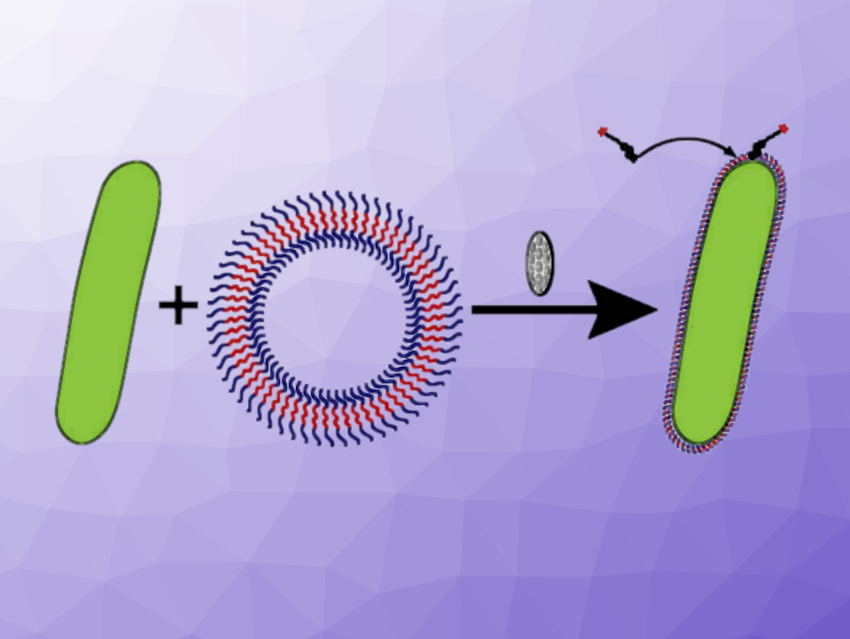

Based on the observation that PL121 forms large vesicles, several times the size of the bacteria (rod-shaped E. coli have a length of 1–2 µm, while PL121 was found to form “giant unilamellar vesicles” (GUVs) with a size of 10 µm), the team used this polymer for co-extrusion with E. coli. Co-extrusion involves both the particles to be coated (in this case, the bacteria) and the coating material being forced through tiny holes, with the aim of covering the core with the material with which it is extruded.

Taking inspiration from the method used to camouflage bacteria, the team used a membrane with micron-sized pores that allowed the bacteria to pass through, but not the vesicles. “The GUVs, which are generally larger than the cutoff, break apart and then reassemble, creating a core–shell structure, with the bacteria forming the core and the polymer solution forming the shell. This technique allows us to create an ultra-thin, uniform coating around each bacterium without damaging the bacteria themselves,” says Andrea Belluati.

Protection and Functionalization

The PL121 jacket left the bacteria alive and also well protected. The team exposed coated and uncoated bacteria to a variety of adverse conditions, including heat, cold, mechanical, and osmotic forces, as well as various chemicals, and found that the coated versions are much more resistant than the uncoated ones. In addition, the polymer coating allowed the researchers to functionalize the surfaces: the insertion of the enzyme alpha-amylase into the PL121 coat produced coated bacteria that broke down starch, while the enzyme lysozyme made the bacteria predatory, leading to them killing their uncoated counterparts.

The researchers believe that it is mainly physical interactions that cause the PL121 polymer to cling tightly to the E. coli cell wall. “We think it’s a mix of the polymer chains interacting with each other (similar to how they form GUVs) and interactions between the bacterial cell wall components and the polymer,” Belluati says. However, as tightly packed and protective as these polymer coatings are, they cannot replicate, and growing cells lose their jackets. Only cells kept at 4 °C retain their coatings, as the researchers observed.

Bacteria in Shells

The team presented the method using E. coli, which is a well-studied model organism, but they are considering using other bacterial species as well. “This is definitely an exciting avenue for future research,” says Belluati. Coated bacteria have the potential for various real-life applications, for example in biomedicine, where bacteria are currently embedded in hydrogels to prevent premature digestion. Since the team has shown that much thinner coatings can also be protective, the amount of encapsulation material could be reduced.

Another field of application could be in biosensing, where minimally protected bacteria survive longer and provide more accurate readings. Finally, the researchers also present a possible solution for the problem of growing bacteria shedding their coats. “Our current research also includes engineering microbes so that they can enzymatically produce their own polymer coating, thus ensuring continuous protection,” says Belluati.

References

[1] An outer membrane-inspired polymer coating protects and endows Escherichia coli with novel functionalities,

A. Belluati, I. Harley, I. Lieberwirth, N. Bruns,

Small 2023, 2303384.

https://doi.org/10.1002/smll.202303384

[2] Camouflaging bacteria by wrapping with cell membranes,

Z. Cao, S. Cheng, X. Wang, Y. Pang, J. Liu,

Nat. Commun. 2019, 10, 3452.

https://doi.org/10.1038/s41467-019-11390-8