Layers of carbon atoms in a honeycomb array are a true supermaterial: The unusually high conductivity and favorable mechanical properties of graphene could further the development of bendable electronics, new batteries, and innovative composite materials for aeronautics and space flight. However, the development of elastic and tough films remains a challenge. Xuzhou Yan, Shanghai Jiao Tong University, Shanghai, China, and colleagues have introduced a method to overcome this hurdle: They linked graphene nanolayers via extendable bridging structures using mechanical bonds.

High-Performance Graphene Films

The special capabilities of microscopic graphene nanolayers often drop off when the layers are assembled into foils, because they are only held together by relatively weak interactions—primarily hydrogen bonds. Approaches that attempt to improve the mechanical properties of graphene foils by introducing stronger interactions have only been partially successful, leaving room for improvement in the stretchability and toughness of the materials.

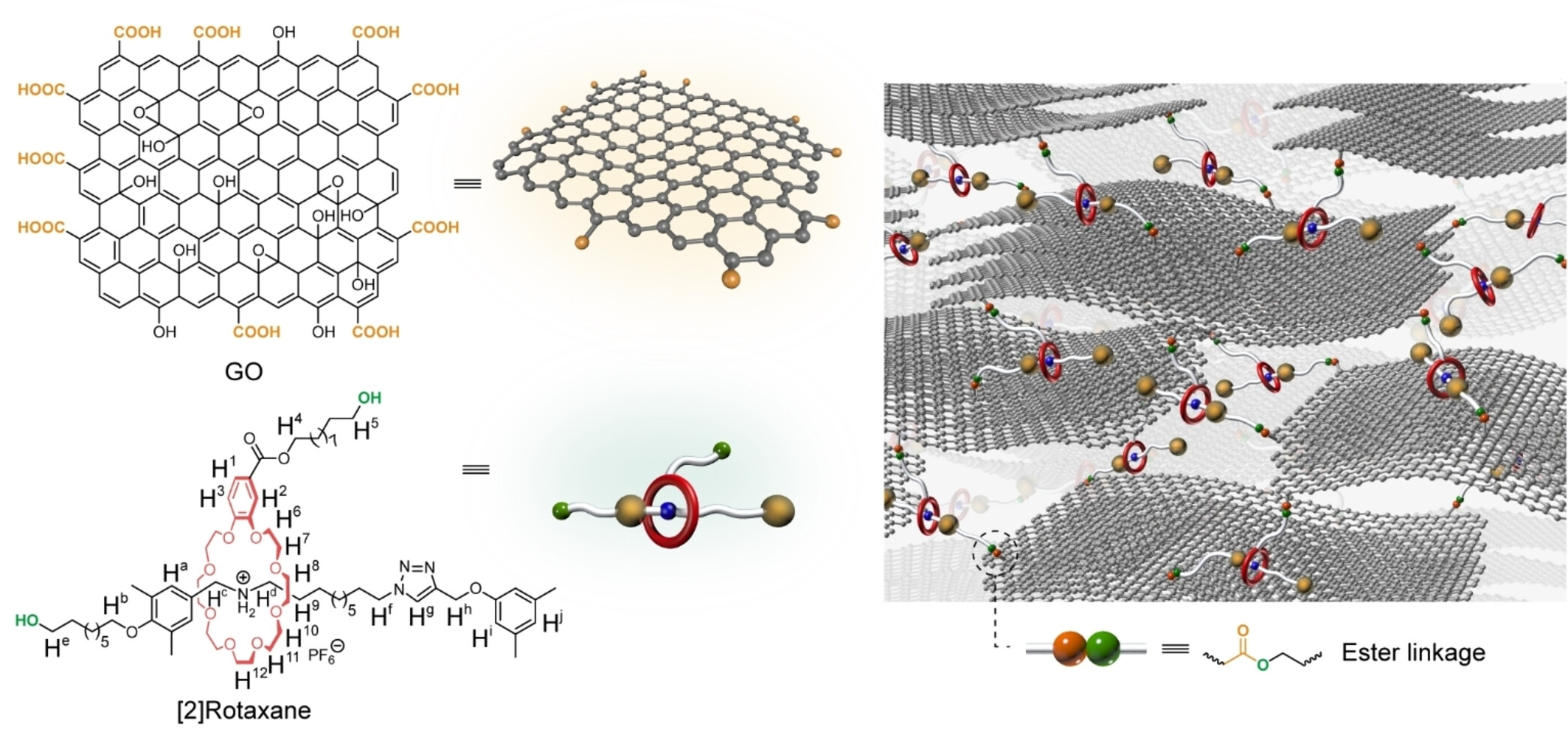

The team used a new approach: They cross-linked graphene nanolayers with mechanically interlocked molecules whose building blocks are not chemically linked, but rather inseparably spatially entangled. The researchers chose to use rotaxanes as their links. A rotaxane is composed of a “wheel” (a large ring-shaped molecule) that is threaded onto an “axle” (a molecular chain). Bulky groups cap the axles to prevent the wheels from coming unthreaded.

Linking Rotaxanes to Graphene

The team built their axle with a charged ammonium group that holds the wheel in a specific position (pictured below). Hydroxyl groups as molecular “anchors” were attached to both the axle and wheel by linkers.

The graphene was oxidized to make graphene oxide, which forms a variety of oxygen-containing groups on both sides of the graphene layer. These include carboxyl groups, which can bind to the OH groups by esterification. This reaction allows the wheel and axle to cross-link the layers, after which the graphene oxide is reduced back to graphene.

Stretchable and Tough Material

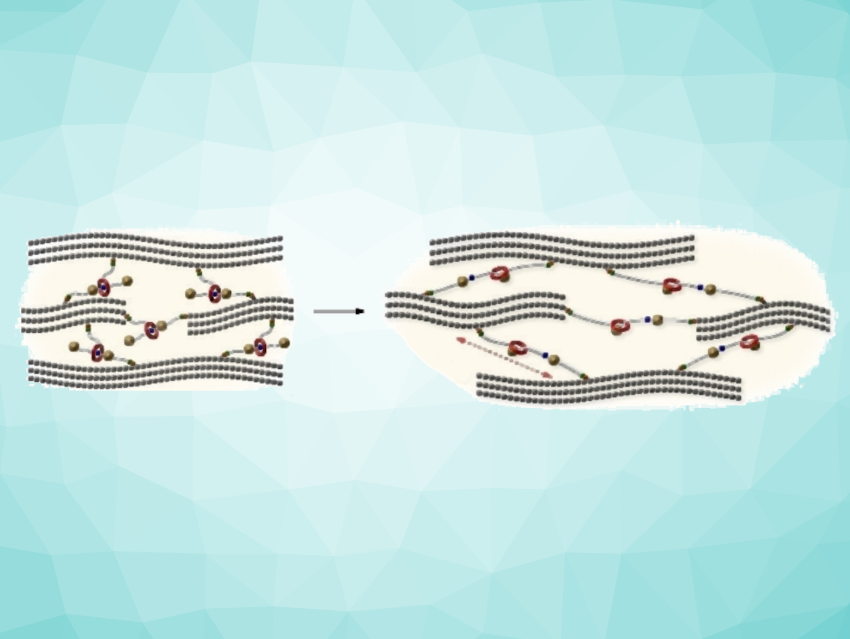

When the films are stretched or bent, the attractive forces between the wheel and the ammonium group on the axle must be overcome, which increases the tensile strength. Increased stress eventually causes the axle to be pulled through the wheel until it “strikes” the end cap. This motion lengthens the rotaxane bridges, allowing the layers to slide across each other, which significantly increases the stretchability of the film.

Flexible electrodes made from this graphene–rotaxane foil could be stretched up to 20 % or bent repeatedly without being damaged. They also retained their high electric conductivity. Only stretching by over 23 % led to fracture.

The new foils are considerably stronger than foils without rotaxanes (247.3 vs 74.8 MPa), as well as more elastic (23.6 vs 10.2 %) and tougher (23.9 vs 4.0 MJ/m3). The team also built a simple “grasping tool” with mechanical joints that were equipped with and actuated by the new foils.

- A Stretchable and Tough Graphene Film Enabled by Mechanical Bond,

Chunyu Wang, Boyue Gao, Fuyi Fang, Wenhao Qi, Ge Yan, Jun Zhao, Wenbin Wang, Ruixue Bai, Zhaoming Zhang, Zhitao Zhang, Wenming Zhang, Xuzhou Yan,

Angew. Chem. Int. Ed. 2024.

https://doi.org/10.1002/anie.202404481