Chips on integrated circuits keep getting smaller, and the materials used around them are subject to greater demands. Benzocyclobutene (BCB) thermosets, for example, can be used as interlayer dielectric materials. However, “traditional” BCB materials require high curing temperatures, which hampers their use in temperature-sensitive applications.

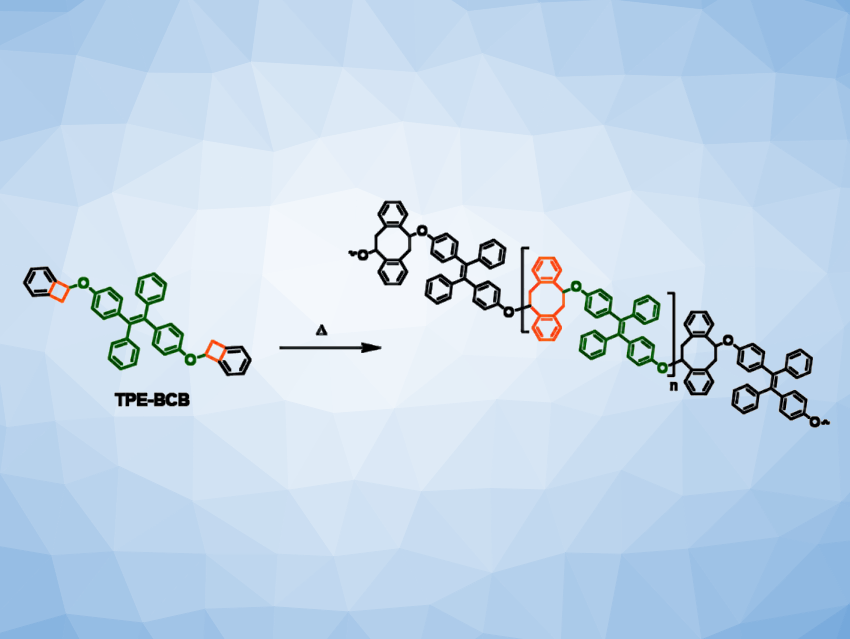

Yan Sun, Henan University, Kaifeng, China, Wenxin Fu, Key Laboratory of Science and Technology on High-Tech Polymer Materials, Chinese Academy of Sciences, Beijing, and University of the Chinese Academy of Sciences, Beijing, and colleagues have developed a tetraphenylethylene-modified BCB monomer (TPE-BCB, pictured). TPE–BCB was synthesized via a Williamson reaction in a yield of 74 %. This monomer can be cured at a lowered ring-opening temperature of 190 °C (reaction pictured), which represents a significant 60 °C reduction compared with conventional BCBs.

Fully cross-linked TPE-BCB resins showed good dielectric properties, mechanical strength, and hydrophobicity. The material can also be used in photolithography together with the azide-based photosensitive agent BAC-E, which can crosslink partially polymerized precursors under UV exposure to create patterns. TPE-BCB also shows an aggregation‐induced emission (AIE) effect, which leads to interesting fluorescence characteristics. Overall, the work could pave the way for new applications of BCB dielectric materials, e.g., in flexible and wearable devices.

- Low‐temperature‐curable and photo‐patternable benzocyclobutene‐derived aggregation‐induced emission‐active polymer dielectrics,

Ziwei Yuan, Meng Xie, Jianlei Qian, Wenjie Fan, Menglu Li, Liao Guo, Yan Sun, Wenxin Fu,

Aggregate 2024.

https://doi.org/10.1002/agt2.487

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)