Plastic waste is an important environmental concern. Generally, only a small part of the produced plastic materials is recycled. Chemical recycling, in which polymers are broken down to give monomers for new materials, can be a useful approach in this context. New chemically recyclable polymers should ideally be produced from easily accessible monomers, show high synthetic efficiency and useful properties, and allow monomer recovery through a simple process.

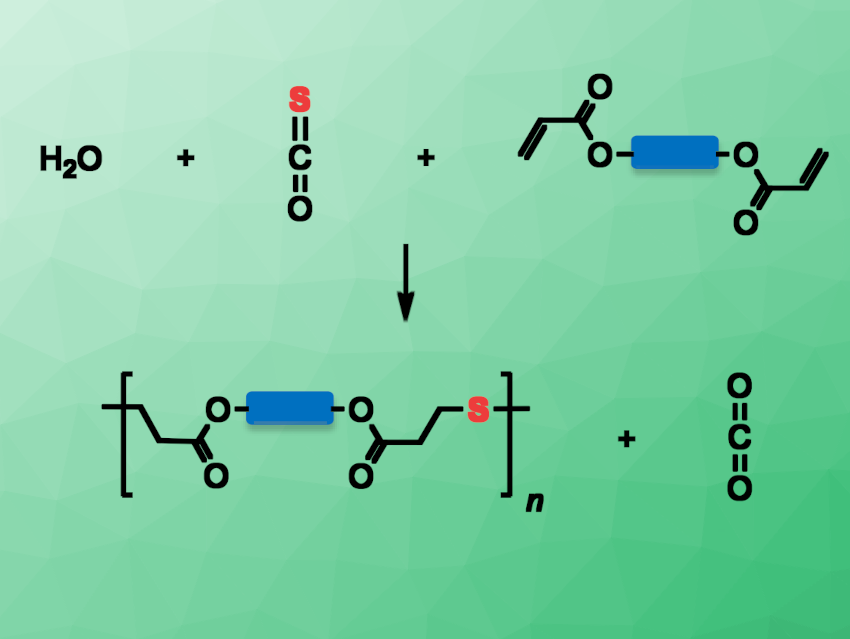

Xinghong Zhang, Zhejiang University, Hangzhou, China, and colleagues have developed a series of chemically recyclable polymers using the first reported cascade polymerization of H2O, COS, and diacrylates (overall reaction pictured). The team used a variety of commercially available organic or inorganic bases, such as guanidines, amidines, amines, alkali metal alkoxides, hydroxides, or carbonates, as the catalyst. Sixteen different diacrylates were employed as substrates. The reactions were performed in air and solvent-free at 60 °C over 4 h.

The team obtained polymers with high molecular weights in nearly stoichiometric amounts. Some of the products show good mechanical properties that are comparable to high-density polyethylene (HDPE). The ester groups in the polymer act as “breaking points” to allow chemical recycling. This recycling can be easily completed via two loops: one involving hydrolysis, esterification, and polymerization and the other involving methanolysis and polycondensation.

The developed method uses abundant feedstocks, is efficient and air-tolerant, employs common organic bases as catalysts, and gives polymers with high molecular weights under mild conditions.

- Chemically recyclable polyethylene‐like sulfur‐containing plastics from sustainable feedstocks,

Yanni Xia, Xinchen Yue, Yue Sun, Chengjian Zhang, Xinghong Zhang,

Angew. Chem. Int. Ed. 2023.

https://doi.org/10.1002/anie.202219251

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)