Polyolefins are widely used plastics. Often, post-consumer plastic waste is burnt or kept in landfills instead of being recycled. Methods for the conversion of polyolefins into useful monomers or other chemical feedstocks would, thus, be useful. However, the cleavage of C–C bonds in polyolefins such as polyethylene (PE) can require large amounts of energy and give a hard-to-control mixture of products. An alternative approach is the chemical recycling of polyethylene waste into a different monomer, which can be repolymerized to obtain plastics with similar properties to PE.

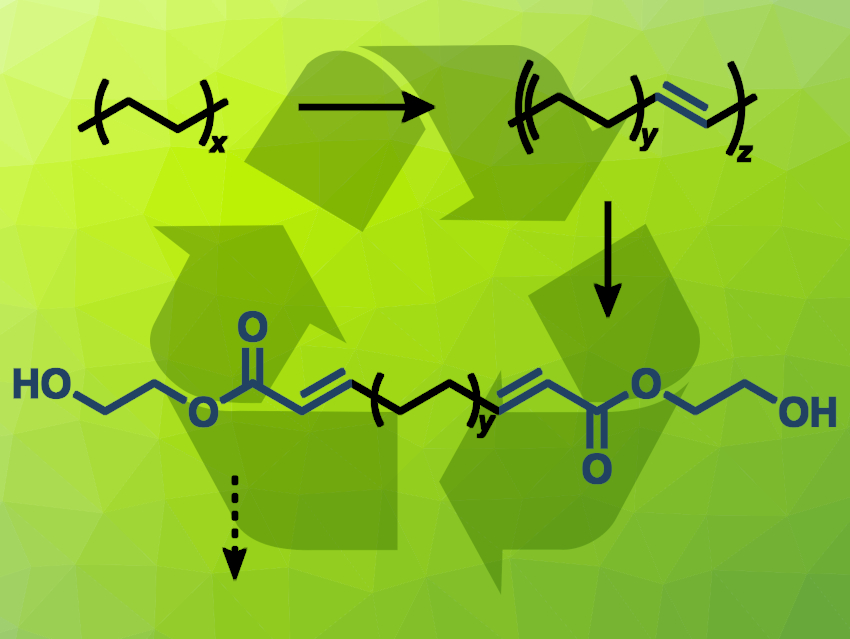

Anne M. LaPointe, Geoffrey W. Coates, Cornell University, Ithaca, NY, USA, Massimiliano Delferro, Argonne National Laboratory, Lemont, IL, USA, and University of Chicago, IL, USA, and colleagues have developed a route for the chemical recycling of high-density polyethylene (HDPE) waste that gives monomers that can be re- and depolymerized in a circular process. The team first dehydrogenated the HDPE using an iridium POCOP ethylene complex as the catalyst (POCOP-H = 1,3,5-[(tBu2)PO]3C6H3), which introduces double bonds (pictured at the top right). The partially unsaturated polymer was then subjected to a cross-metathesis reaction with 2-hydroxyethyl acrylate to break the chains down into smaller parts and introduce functional groups that can be used for repolymerization (product pictured).

The resulting monomers can be hydrogenated to remove the C=C double bonds and can then be used to make new polymers. Partial aminolysis can be used to create a monomer mixture that is suitable for cross-linking, improving the mechanical properties of the resulting materials. The developed monomers can be polymerized to give a material with comparable mechanical and thermal properties to HDPE. After use, depolymerization can be used to recover the monomers and allow chemical recycling.

- Catalytic Chemical Recycling of Post-Consumer Polyethylene,

Alejandra Arroyave, Shilin Cui, Jaqueline C. Lopez, Andrew L. Kocen, Anne M. LaPointe, Massimiliano Delferro, Geoffrey W. Coates,

J. Am. Chem. Soc. 2022.

https://doi.org/10.1021/jacs.2c11949