The megatrends shaping our world include climate change and renewable energy as well as urbanization, along with all their attendant phenomena. Climate change carries the greatest transformative potential, and a shift away from the fossil economy is underway in the EU. The rapidly escalating energy crisis is also accelerating the already ongoing green transition.

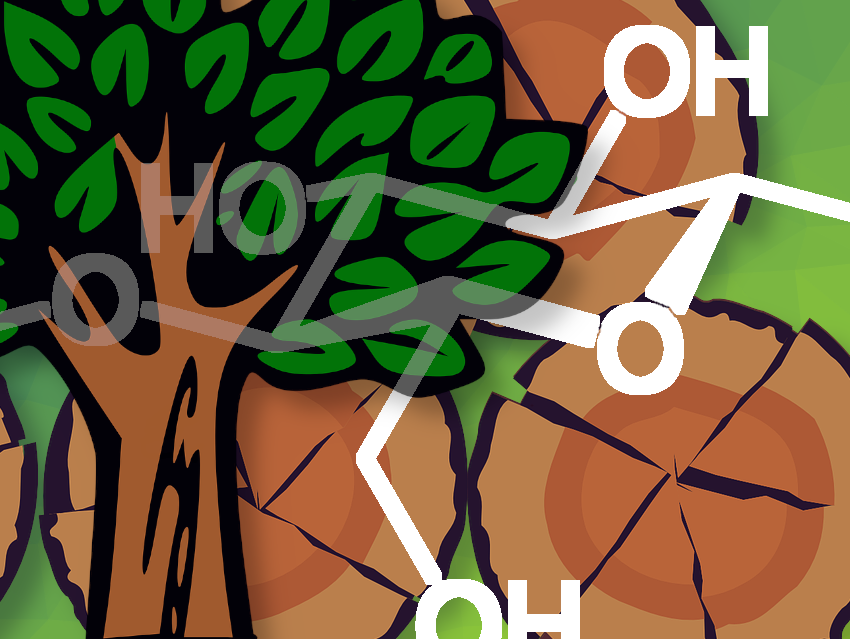

Sustainability requirements, urbanization, and the decreasing sizes of households are all examples of aspects that support the growth of forest industry businesses. New wood-based products, as alternatives to oil-based products, are gaining traction, including textiles, liquid biofuels, platform chemicals, plastics, and packaging. Demand for wood products is also increasing due to more and smaller households needing furniture and packaging, for example. Urbanization takes up space and encourages deforestation.

Wood-fiber-based textiles are a growing, key new product group of the forest bioeconomy, with a very good chance of becoming a global volume product. Elsewhere, the growth of e-commerce, alongside urbanization and smaller household sizes, is increasing the need for packaging. As a result, the demand for paperboard has also grown rapidly.

At the same time, the consumption of several paper grades continues to shrink. This helps to keep the wood consumption in balance: The precious wood raw material is steered more and more towards the growing markets for paperboards and new end uses such as wood-fiber-based textiles, while conventional paper production needs less.

On-Going Studies Take an In-Depth Look at Cellulose

Finland engages in systematic work to increase wood’s added value. This is apparent in the close collaboration between research and industry in this field, for example.

Materials Research

Materials research is being carried out, particularly at FinnCERES, a Flagship Programme of the Academy of Finland, and the joint materials bioeconomy competence center of Aalto University, and VTT Technical Research Center of Finland. FinnCERES aims to find answers to the most fundamental questions about the degradation and reconstruction of lignocellulose and to develop new, competitive bio-based materials.

In practice, the study of new materials means the study of lignocellulose, given that an understanding of the properties of wood-based biomass also enables the production of new products with high added value. The full potential of the modern wood-based forest bioeconomy with its products cannot be tapped without a deep knowledge of chemistry. Without chemistry, we would not be able to reach deeper into nanocellulose, which is the basis for numerous new products.

Cellulose know-how is the path towards bio-based textiles, for example, as well as plastic substitutes, optics, and the new raw materials used by the pharmaceutical and cosmetics industries. Indeed, cellulose can even be used as an ingredient in ice cream.

The commercialization of inventions also requires encouragement and connections because the road from a lab to practical and commercial solutions—in other words, actual innovations—is a long one. This is also why seamless cooperation between research and the corporate world is so crucially important.

The Forest Industry’s Investment Surge

The Finnish forest industry has invested heavily in both Finland and overseas in recent years. In Finland alone, around 20 investment projects of the forest industry are currently set to begin or are already underway.

One of the largest ongoing or planned facility investments in Finland is Metsä Fibre’s bioproduct mill under construction in Kemi, which, at EUR 1.85 billion, is Finland’s largest forest industry investment of all time [1]. The fossil-free mill will produce 1.5 million tonnes of softwood and birch pulp annually, as well as 2 TWh of renewable electricity per year, which equals to roughly 2.5 % of Finnish total electricity production. In the middle of the current energy turmoil in Europe, the positive energy balance of state-of-the-art bioproduct mills like in Kemi has not only a major positive impact on the profitability of these investments, but such facilities are also major players in implementing the concrete green transition away from fossil-based energy sources.

Another plan with the potential to reach the billion-euro mark is being drawn up by Stora Enso, another renewable materials company, which announced in October 2022 a EUR 1 billion investment to convert the decommissioned paper machine at its Oulu mill into a large-scale consumer board line [2]. Part of the conversion at Oulu has already been implemented. The final conversion will transform Europe’s largest paper mill into its largest paperboard mill. At the same time, the Oulu mill becomes a landmark and prime example of the transformation taking place in the industry: the former million-ton paper mill moves towards renewable packaging materials.

On the biomaterials side, Stora Enso invested in the production of dry lignin in Sunila Mill, Kotka, Finland, back in 2015 [3]. Last year, the investment was complemented with a test facility in which anodes of lithium-ion batteries made from graphite are replaced with the Lignode® material for electric car batteries, for example. Graphite is either synthesized from fossil materials or mined under less than satisfactory conditions whereas lignin is a renewable material available as a side-stream in cellulose fiber production.

New products have also allowed the forest industry to expand its product range in the consumer products sector. An example of these new products is the beverage bottles made for Coca-Cola by UPM, Helsinki, Finland, from forest industry side streams. The production of the bio-based bottles will be centralized at UPM’s biorefinery in Leuna, Germany [4]. UPM will produce monoethylene glycol (MEG), the key ingredient in PET bottles, from woody biomass. The total annual capacity of the biorefinery will be 220,000 tons of bio-monoethylene glycol (BioMEG), bio-monopropylene glycol (BioMPG), and lignin-based renewable functional fillers (RFF) made from certified hardwood from the region of Germany.

The aforementioned bio-textiles likewise possess the potential for large production volumes. Different highly advanced production technologies have been developed by Spinnova, Infinited Fiber Company, and Metsä Spring, among others. The new textile technologies of many of these companies are in their pilot phases or close to an industrial-scale investment. Most recently, in June 2022, Infinited Fiber, Espoo, Finland, announced a EUR 400 million investment in a facility to be built in Kemi [5]. The new plant, with the capacity to produce 30,000 tonnes of textile fiber, is set to start up in 2025.

Their fiber, Infinna™, is produced from cellulose-rich waste such as discarded textiles, used cardboard, or even rice straw, and blends perfectly with fibers such as organic cotton and viscose. The fiber requires only a fraction of the water needed to produce a comparable amount of cotton and is fully biodegradable. According to the company, Infinna™ has the natural look and feel of cotton, as well as unique properties that make it ideal for use in a range of fabrics—from soft single jersey and French terry to denim.

A Podcast and Digital Learning Environment to Point the Way Forward

The present and future of the forest industry were on prominent display at the international PulPaper event held at Messukeskus, Helsinki, in June 2022 simultaneously with the chemicals industry events ChemBio Finland and Helsinki Chemicals Forum. During the PulPaper event, we received abundant feedback from attendees interested in learning more about these interesting forest industry innovations. In November 2022, it was announced that this leading international event will be organized again on April 10 to 11, 2024 [6].

To this end, the Finnish Forest Products Engineers’ Association releases an eight-episode podcast series. In the series, which was launched in September 2022, the forest bioeconomy’s and forest industry’s future technologies and their backgrounds are being discussed with some of the foremost experts.

You can also find further information on the forest industry’s topical technologies, products, and significance in solving global challenges in general by visiting the digital learning environment ForestBioFacts.

References

[1] Kemi bioproduct mill project, Metsä Fibre. (accessed August 27, 2022)

[2] Stora Enso invests in conversion to accelerate growth in renewable packaging, Stora Enso. (accessed December 22, 2022)

[3] How we’re making batteries from trees: Lignode® by Stora Enso, Stora Enso. (accessed August 27, 2022)

[4] German Federal President Frank-Walter Steinmeier visits UPM Biochemicals Project in Leuna, UPM Press Release June 23, 2021. (accessed August 27, 2022)

[5] Infinited Fiber picks site of shut paper plant in Finnish Lapland for its planned EUR 400 million textile fiber factory investment, Infinited Fiber Press Release June 20, 2022. (accessed August 27, 2022)

[6] PulPaper returns completely renewed in 2024, Messukeskus, Helsinki, Finland (accessed December 22, 2022)

Author

Antti Lindqvist

Managing Director, D.Sc. (Tech.)

Finnish Forest Products Engineers’ Association (PI)

[email protected]