Single-atom catalysts can be very useful in heterogeneous catalysis. This is due to their ability to use critical raw materials efficiently as well as their excellent performance. However, these catalysts are often studied using slurry or packed-bed reactors, which are suboptimal for industrial use.

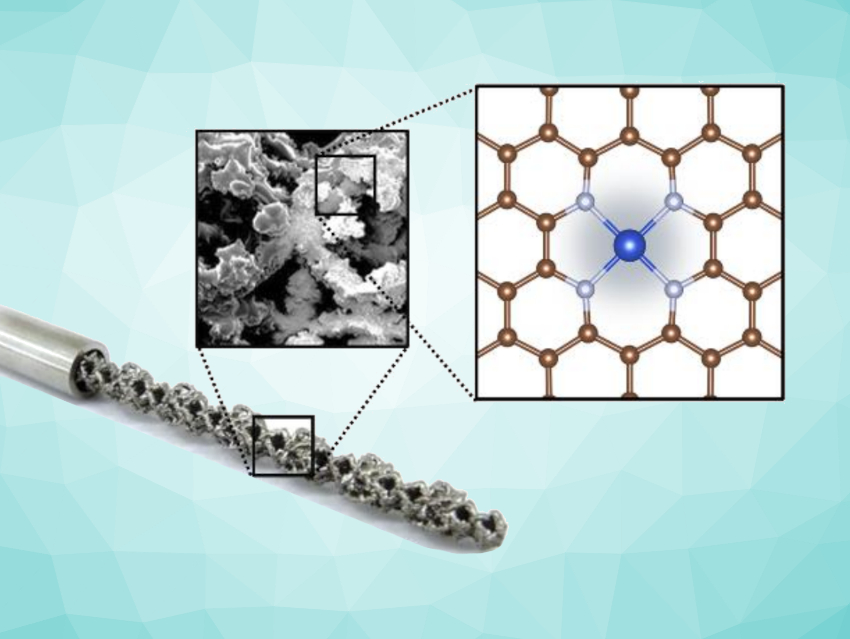

Gianvito Vilé, Politecnico di Milano, Italy, and colleagues have developed a structured catalytic reactor by immobilizing a thin single-atom catalyst (SAC) film onto 3D-printed metal structures (pictured). The team first prepared a powdered copper single-atom catalyst on mesoporous carbon nitride (mpgC3N4). Then, they used 3D printing with an electron beam melting (EBM) method to create reactors called catalytic static mixers (CSMs) from stainless-steel powder. These reactors were coated with a thin film of the catalyst.

The resulting catalytic reactor was used for the continuous-flow hydrogenation of benzaldehyde and furfural. It showed stable catalytic activity for several hours on stream. Industrially, structured catalytic reactors have several advantages compared with traditional packed-bed reactors, including low catalyst inventory, low pressure drop, and efficient mass/heat transfer. Thus, this work may have implications for the large-scale utilization of these catalytic materials.

- 3D‐Printed Structured Reactor with Integrated Single‐Atom Catalyst Film for Hydrogenation,

Gianvito Vilé, Derrick Ng, Zongli Xie, Ivan Martinez Botella, John Tsanaktsidis, Christian H. Hornung,

ChemCatChem 2022.

https://doi.org/10.1002/cctc.202101941