Flow chemistry is increasingly being adopted in both pharmaceutical and fine chemicals research to prepare molecules. This is due to its increased safety, cost-saving potential, ease of scale-up, and greater control over reaction parameters. However, commercial systems typically cost upwards of $20,000 and take up valuable fumehood space representing a barrier to entry for researchers and educators.

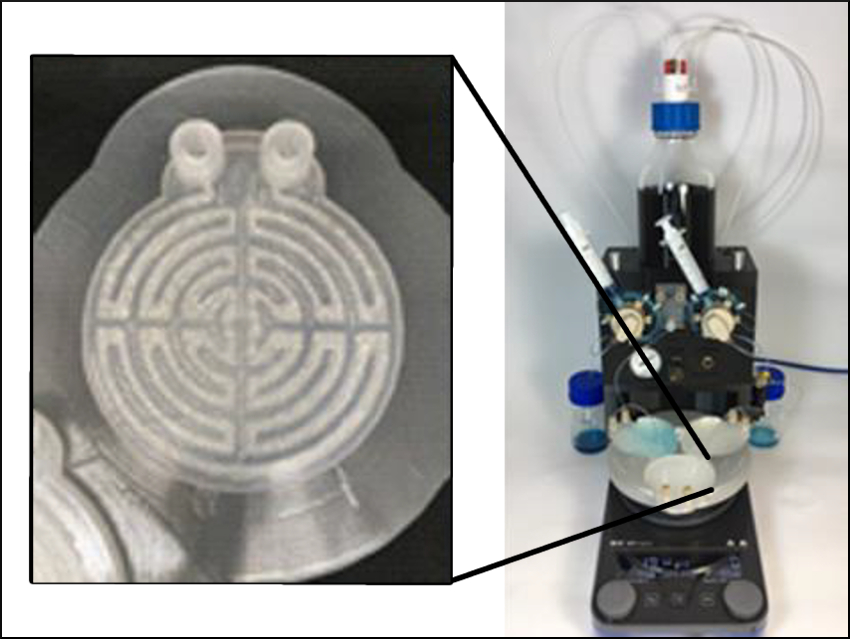

Stephen Hilton, UCL School of Pharmacy, London, UK, and colleagues have developed a low-cost, low-footprint, modular 3D printed flow reactor for synthetic chemists. The system uses compressed air or nitrogen to drive flow rather than expensive pumps and is attached to a stirrer hotplate, both of which are commonly found in laboratories.

The team used the equipment to carry out SNAr reactions to prepare a set of biaryl ethers. They used 3D-printed polypropylene circular disk reactors (CDR). The residence time of the reaction was altered by simply attaching additional CDRs to the flow setup. Flow rates were controlled with HPLC capillary tubing. It acted as hydraulic resistors offering back pressure control for reactions done at elevated temperatures.

- Modular 3D Printed Compressed Air Driven Continuous-Flow Systems for Chemical Synthesis,

Matthew Penny, Zenobia X. Rao, Bruno Peniche, Stephen Hilton,

Eur. J. Org. Chem. 2019.

https://doi.org/10.1002/ejoc.201900423