The chemical industry uses large amounts of fossil resources to produce compounds, e.g., for plastics, pharmaceuticals, cosmetics, and nutrition. Enzymes could play an important role in replacing such syntheses by environmentally friendly, green methods that convert renewable biomass into value-added products.

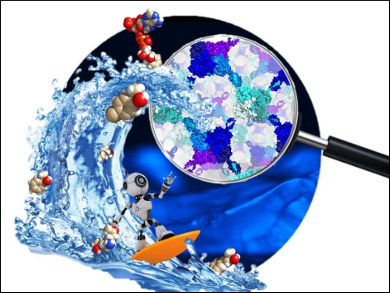

Microreactors offer many advantages in process engineering, such as improved heat and mass transfer, and are increasingly used in industry. However, their use for biocatalytic processes is still in its infancy, since enzymes are difficult to immobilize in the reactors. While support materials can be used for this purpose, they consume valuable reactor space, which is then no longer available for the biocatalysts.

Christof M. Niemeyer and colleagues, Karlsruhe Institute of Technology (KIT), Germany, have developed a catalytically active biomaterial that simplifies the practical use of enzymes in microreactors. The developed “self-assembling” enzyme materials function similarly to a two-component adhesive. Upon mixing, the enzymes spontaneously form a gel-like polymer that can be easily incorporated into miniaturized flow reactors and then used for chemical syntheses. The gelation strategy is based on a pair of genetically encoded reactive partners on the enzymes.

The novel gels allow the reactor space to be filled with a maximum amount of active biocatalyst. In addition, they are completely recyclable, biodegradable, have a high stability, and provide high yields. The team demonstrated that the biocatalytic gels can be used for the stereoselective syntheses of chiral alcohols. They anticipate that, in the long term, the materials can be used in machine-assisted processes for the sustainable production of value-added chemicals.

- Self-Assembling All-Enzyme Hydrogels for Flow Biocatalysis,

Theo Peschke, Patrick Bitterwolf, Sabrina Gallus, Yong Hu, Claude Oelschlaeger, Norbert Willenbacher, Kersten S. Rabe, Christof M. Niemeyer,

Angew. Chem. Int. Ed. 2018.

https://doi.org/10.1002/anie.201810331