Heavy crude oil is too viscous to be transported in pipelines. The formation of oil-in-water emulsions reduces the viscosity effectively, but surfactants are needed to stabilize the emulsions during transport. A fast separation of the two phases at the end of the pipeline is useful. CO2-switchable surfactants satisfy both requirements. When CO2 is introduced, the raised acidity destroys the surfactant and allows the emulsion to separate into its aqueous and oil phase.

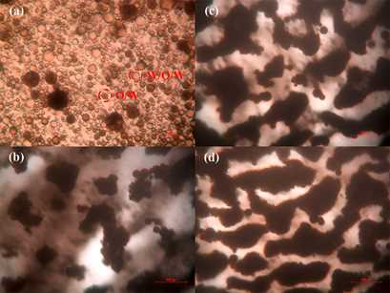

Hongsheng Lu, Southwest Petroleum University and Engineering Research Center of Oilfield Chemistry, both Chengdu, China, and colleagues have studied three different tertiary amines for their ability to form a CO2-switchable oil-in-water emulsion with the naphthenic acid naturally present in heavy crude oil. N,N‐Dimethylbutylamine, N,N‐dimethyloctylamine, and N,N‐dimethyldodecylamine were used to prepare heavy crude oil emulsions. Then, CO2 was bubbled into the emulsion at room temperature until the separation of heavy crude oil and the water phase (process pictured) was achieved.

While all tested amines formed emulsions, N,N-dimethylbutylamine was determined as the best choice. Not only was it the most stable option, but it was also the easiest to separate again upon introduction of CO2. The differences in stability and emulsion separation were attributed to the length of the hydrophobic chain and interactions with other components of the oil. Since no harsh conditions are required, this method presents an environmentally friendly and low-cost option to prepare heavy crude oil for pipeline transport

- Tertiary Amine-Naphthenic Acid Self-Assembled Surfactants for Viscosity Reduction of Crude Oil,

Dongfang Liu, Yuxin Suo, Jiang Tan, Peiyao Zhu, Jihe Zhao, Baogang Wang, Hongsheng Lu,

Chem. Eng. Technol. 2018, 41, 2266–2273.

https://doi.org/10.1002/ceat.201700489The article is part of a Chemical Engineering & Technology Special Issue on Bioenergy.