Material screening is essential to develop advanced exhaust treatment systems. During the last decade, high-throughput (HT) methods for the evaluation of heterogeneous catalysts for different chemical processes have become established tools. In the field of automotive catalysis, however, a relatively low number of studies report on the use of HT screening technologies and test results.

Andreas Sundermann and Olga Gerlach, hte GmbH, Heidelberg, Germany, revealed in two case studies how fully automated test equipment in combination with dedicated software workflows for data reduction allow for rapid screening of parameter spaces as well as material properties relevant for exhaust gas catalyst development. In a first study related to the field of Diesel exhaust aftertreatment it was demonstrated how test conditions affect light-off temperatures observed in steady state tests.

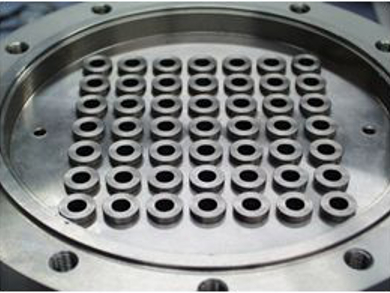

The second study relevant for three way catalytic converters showed the effect of chemical composition on the observed dynamic oxygen storage capacity. With a single 48-fold testing plate the impact of Ce and Pd content on fresh and aged catalysts was evaluated.

The researchers demonstrated that HT screening provides high data quality. If used in combination with proper experimental design, this gives a rational approach to catalyst development and optimization.

- High-Throughput Screening Technology for Automotive Applications,

Andreas Sundermann, Olga Gerlach,

Chem. Ing. Tech. 2014, 86, 1941–1947.

DOI: 10.1002/cite.201400059