Column trays are used in a wide range of destillation separation processes. Sieve and float valve trays are the two most common plates. Disadvantages of sieve trays include weeping, limited operation flexibility, and low mass transfer efficiency. High manufacturing cost, high pressure drop, and bad anti-choking are some of the drawbacks of float valve trays. Consequently, the trend goes to trays with higher mass transfer efficiency, larger capacity, and lower pressure drop.

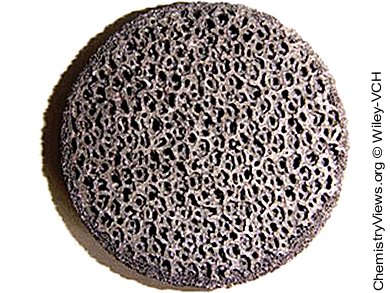

Hong Li, Tianjin University, China, and colleagues investigated a novel tray using SiC ceramic foam. They studied the hydrodynamic and mass transfer characteristics of the SiC foam column tray (SFCT) in different pilot plants. The tray was made of thin slices of SiC foam material with a high specific surface area.

The experimental results indicate that the SFCT exhibits better performances in both hydrodynamic and mass transfer properties than the F1 float valve tray since it has a lower pressure drop, no weeping, lower entrainment, higher height of the clear liquid, and larger mass transfer efficiency. Due to the special structure of the SiC foam, the novel tray has a larger opening ratio than the traditional trays which allows a lower pressure drop without weeping and a wider operation range of gas velocity.

Based on these results, the SFCT can be considered as a good potential tray for distillation.

- Hydrodynamic and Mass Transfer Performances of a New SiC Foam Column Tray,

Luhong Zhang, Xuekuan Liu, Hong Li, Hong Sui, Xingang Li, Jinsong Zhang, Zhenming Yang, Chong Tian, Guohua Gao,

Chem. Eng. Technol. 2012.

DOI: 10.1002/ceat.201200032