Reaction mixtures in analytical and preparative laboratory work are usually captured and subsequently processed using typical laboratory equipment. Expensive semi-preparative or preparative chromatography can only be used for limited product separation and purification. It is mostly applied to the isolation of highly pure, thermally unstable, optically active and expensive products such as the active ingredients deployed by the pharmaceutical industry and where other separation processes are inapplicable.

Volker Hessel, Eindhoven University of Technology, The Netherlands, and colleagues present a prototype of a microrectification apparatus (MRA) which can be used for the separation of liquid mixtures on the analytical and preparative scale and which can be operated under all conditions — batch, semi-batch, continuous.

Depending on the requirements, the apparatus offers the possibility to work under reduced or atmospheric pressure. A connection of two or more such devices in series could fractionate difficult-to-separate systems with very small boiling point differences or azeotropic mixtures into their components. A higher throughput could be achieved by parallel operation of multiple MRA.

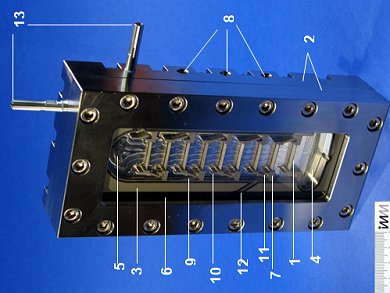

Image: (1) Plate, (2) housing, (3) plate inlay, (4) column bottom,

(5) column top, (6) viewing window, (7) plate holder,

(8) holes for heating cartridges, (9) downcomer, (10) outlet weir,

(11) inlet weir, (12) feed, (13) coolant inlet and outlet.

© Wiley-VCH

- Development of a Microrectification Apparatus for Analytical and Preparative Applications,

A. Ziogas, V. Cominos, G. Kolb, H.-J. Kost, B. Werner, V. Hessel,

Chem. Eng. Technol. 2012, 35(1), 58–71.

DOI: 10.1002/ceat.201100505