Slim liquid-liquid reactors are widely used in process industries, e.g., in polymerization reactions like polyvinylchloride (PVC) production processes. Growing markets and economies lead to higher production rates. To achieve this, a better understanding of slim reactors on the macro-level used for polymerization reactions is required.

A team around Matthias Kraume, Technische Universität Berlin, Sebastian Altwasser, Anhalt University of Applied Sciences, and Torsten Rehm, Vinnolit GmbH, Burghausen, all Germany, carried out detailed experiments and simulations to determine an optimum configuration for a multiple-impeller application and to analyze of the influence of baffle length on single-stage impellers in a slim reactor. Power consumption, mixing time and minimum dispersion speed were determined for five different stirrers under turbulent conditions. According to the results of their study a recommendation for an optimum impeller configuration is given.

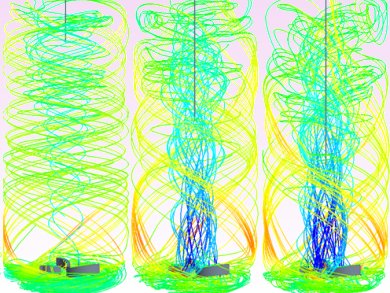

- Flow Field Analysis of Stirred Liquid-Liquid Systems in Slim Reactors

S. Maaß, T. Eppinger, S. Altwasser, T. Rehm, M. Kraume,

Chem. Eng. Technol. 2011, 34 (8).

DOI: 10.1002/ceat.201100033