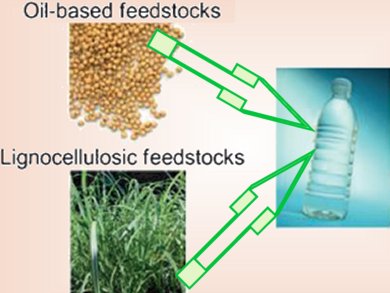

Polyethylene terephthalate (PET) is a widely used plastic with applications ranging from beverage containers to synthetic fibers. Conventionally, PET is mass-produced from fossil-fuel-based materials such as p-xylene obtained from crude oil.

Mika Shirmizu and Dean Toste, University of California, Berkeley, USA, have developed a sustainable method for PET production that uses solely bio-renewable resources. They use 2,5-dimethylfuran derived from lignocellulosic biomass and acrolein produced from glycerol, a side product of biodiesel production, to make p-xylene. The route consisted of a Diels–Alder reaction, oxidation, dehydrative aromatization, and decarboxylation and was designed to maximize atom economy and avoid toxic byproducts.

Bio-derived p-xylene was obtained in 34 % overall yield and could easily replace crude-oil derived p-xylene in the industrial production of PET with few changes to the downstream infrastructure and operational methods.

Images: © Wiley-VCH

- On the Diels–Alder Approach to Solely Biomass-Derived Polyethylene Terephthalate (PET): Conversion of 2,5-Dimethylfuran and Acrolein into p-Xylene

M. Shiramizu, F. D. Toste,

Chem. Eur. J. 2011.

DOI: 10.1002/chem.201101580