Superhydrophobic surfaces have water‐repellent, antifrost, and antifreezing properties, as well as self‐cleaning abilities. Superhydrophobic fibers, for example, can be used to make textiles that are easy to clean. However, existing superhydrophobic fabrics have issues with breathability and color stability. Their production can also require fluorine processing agents that are harmful to human health and the environment.

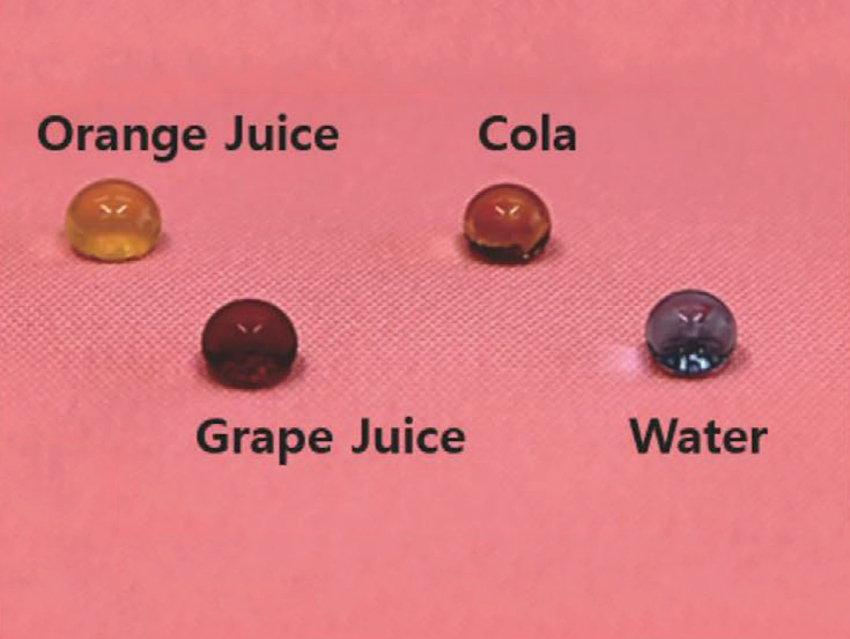

Ji‐Hyun Oh, Seoul National University, Republic of Korea, and Massachusetts Institute of Technology (MIT), Cambridge, MA, USA, and Chung Hee Park, Seoul National University, have developed a colorful, fluorine-free, superhydrophobic polyester fabric (pictured). The team used an optimized alkaline hydrolysis process to create nanocraters on the surface of polyester fabric. The nanorough structure created by these tiny craters renders the surface superhydrophobic. The fabric was then dyed with two different disperse dyes. Disperse dyes are water-insoluble dyes that can dye polyester fibers and are based on an azobenzene or anthraquinone scaffold. The fibers were then thermally aged.

The resulting polyester fabrics are superhydrophobic with static contact angles over 160°. They also show good color fastness as well as breathability and self‐cleaning abilities. The material is nontoxic and environmentally friendly and can be readily recycled.

- Colorful Fluorine-Free Superhydrophobic Polyester Fabric Prepared via Disperse Dyeing Process,

Ji-Hyun Oh, Chung Hee Park,

Adv. Mater. Interfaces 2020.

https://doi.org/10.1002/admi.202000127