Salt templates, usually made from NaCl, can be used to create porous materials. The salt structure is infiltrated with the desired material and then leached out to form the pores. However, this method usually provides little control over the resulting pore structure.

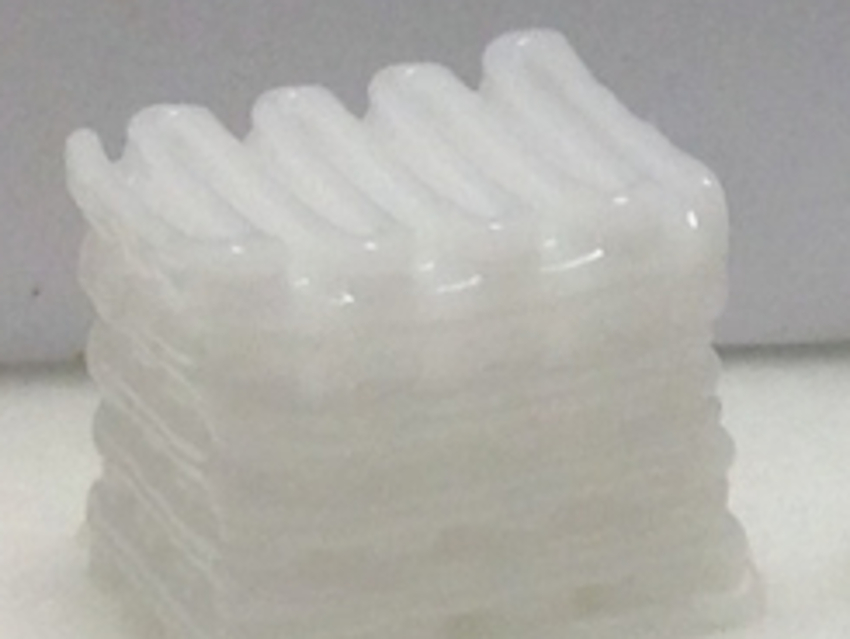

Martina Cihova, André R. Studart, Jörg F. Löffler, and colleagues, Swiss Federal Institute of Technology (ETH) Zurich, have developed a technique that allows the production of complex, controlled shapes made from NaCl. These shapes can then be used as templates for salt leaching. The team combined NaCl with paraffin oil and the surfactant bis(2‐ethylhexyl) sulfosuccinate sodium salt to give a printable paste. This paste was used for 3D printing to create the desired shapes. The printed shapes were dried and sintered to give NaCl templates (pictured).

As a proof-of-concept, the team used the templates to prepare magnesium scaffolds with ordered porosity. The NaCl templates were infiltrated by a magnesium melt and then removed by leaching with an aqueous solution of NaOH.

The method can be used to create a wide range of shapes, which are precisely replicated by the magnesium. According to the researchers, the technique can potentially be extended to other scaffold materials.

- 3D Printing of Salt as a Template for Magnesium with Structured Porosity,

Nicole Kleger, Martina Cihova, Kunal Masania, André R. Studart, Jörg F. Löffler,

Adv. Mater. 2019.

https://doi.org/10.1002/adma.201903783