In 3D bioprinting, hydrogels loaded with living cells are deposited layer by layer to create tissue-like materials. The printing materials not only have to be compatible with the printing process, but also with the cells. Many cells require a specially designed microenvironment that mimics their natural extracellular matrix for proper growth.

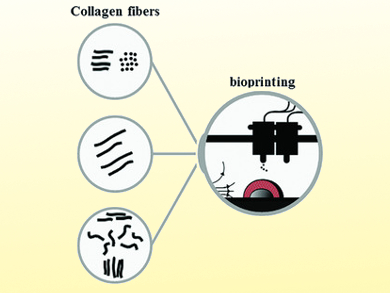

Additionally, many natural tissues are characterized by a well-designed inhomogeneity. In cartilage, for example, the outer layer is characterized by horizontally aligned collagen fibers, whereas the fibers in the middle layer are aligned randomly and those in the inner layer are aligned vertically (perpendicular to the joint) to support the mechanical load.

Daniela Filipa Duarte Campos and colleagues, RWTH Aachen University, Germany, have applied a magnetic field during the 3D bioprinting process to align collagen fibers in the desired manner. The team combined cell‐ and collagen-loaded hydrogels with protein-coated iron nanoparticles and used a custom‐made 3D bioprinter to create the desired structures. In the presence of a magnetic field, the collagen fibers aligned during the gelation of the hydrogel, caused by the iron nanoparticles moving in one direction through the material.

Using this approach, the team was able to engineer complex structures resembling natural cartilage. By bioprinting with varying fiber alignment, the chondrogenic potential of the tissue, i.e., the formation of mature cartilage, was also improved. The developed concept could also be applicable to other tissues, e.g., corneal or dental tissues.

- Incorporating 4D into Bioprinting: Real-Time Magnetically Directed Collagen Fiber Alignment for Generating Complex Multilayered Tissues,

Marcel Betsch, Catalin Cristian, Ying-Ying Lin, Andreas Blaeser, Jan Schöneberg, Michael Vogt, Eva Miriam Buhl, Horst Fischer, Daniela Filipa Duarte Campos,

Adv. Healthcare Mater. 2018.

https://doi.org/10.1002/adhm.201800894