Self-healing polymers can autonomously repair physical damages such as scratches and cuts. This extends the lifetime of such polymers and makes them attractive for many applications, e.g., in protective surface coatings and sensors. Important properties of self-healing polymers are efficient recovery, transparency, and robustness. However, self-healing and robustness are usually contradictory and difficult to optimize simultaneously. Mechanical robustness is achieved through tightly packed hard polymer segments that restrict chain mobility, but that same mobility is necessary for self-healing.

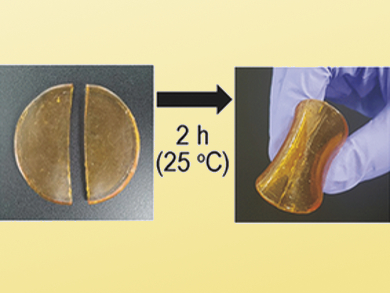

Sung Yeon Hwang, Dongyeop X. Oh, Jeyoung Park, Korea Research Institute of Chemical Technology (KRICT), Ulsan, and University of Science and Technology (UST), Daejeon, both Republic of Korea, and colleagues have designed a self-healing and transparent thermoplastic polyurethane (TPU) with high tensile strength and toughness (6.8 MPa and 26.0 MJ m–3, respectively). The TPU contains hard isophorone diisocyanate (IP) segments that have adequate packing density to achieve both efficient chain mobility and good mechanical properties. Additionally, bis(4-hydroxyphenyl)disulfide is embedded into the IP segments. This compound allows self-healing (pictured) through disulfide metathesis at moderate temperatures without external stimuli.

The researchers demonstrated that the IP-containing TPU achieves full scratch and almost full cut recovery within two hours at room temperature. Moreover, the team prepared a scratch-repairing sensor by patterning microsized silver electrodes on the TPU film. After scratching the film, electrical healing occurred within 25 min, showing the material’s potential for applications in self-repairing electronic sensors.

- Superior Toughness and Fast Self-Healing at Room Temperature Engineered by Transparent Elastomers,

Seon-Mi Kim, Hyeonyeol Jeon, Sung-Ho Shin, Seul-A Park, Jonggeon Jegal, Sung Yeon Hwang, Dongyeop X. Oh, Jeyoung Park,

Adv. Mater. 2017.

DOI: 10.1002/adma.201705145

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)