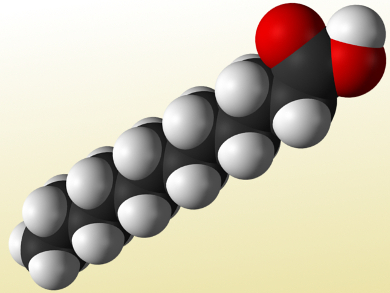

Fatty acids are important compounds for the industrial production of, e.g., soap or nylon. Their synthesis, however, often involves harsh conditions or toxic reagents such as carbon monoxide. Milder processes, on the other hand, often produce a large number of byproducts.

Ruben Martin, Institute of Chemical Research of Catalonia (ICIQ), Tarragona, Spain, and Institució Catalana de Recerca i Estudis Avançats (ICREA), Barcelona, Spain, and colleagues have designed a nickel catalyst that can promote the coupling of saturated hydrocarbons to CO2 at atmospheric pressure, giving pure fatty acids. The hydrocarbons used are first brominated, which gives a mixture of alkyl bromides. The team then combined NiI2, a phenanthroline-based ligand, and Mn powder with the alkyl bromides under a CO2 atmosphere to create the desired product by carboxylation.

The nickel catalyst first reacts with the substrate at the brominated site but then migrates along the alkyl chain, which causes the mixture of brominated compounds to be transformed to a single fatty acid as the product. The selectivity of reaction can be tuned by changing the temperature, causing the nickel to “slide” to different sites in the substrate before the final carboxylation step. According to the researchers, this approach for the synthesis of fatty acids is greener and more sustainable than currently used methods.

- Remote carboxylation of halogenated aliphatic hydrocarbons with carbon dioxide,

Francisco Juliá-Hernández, Toni Moragas, Josep Cornella, Ruben Martin,

Nature 2017.

https://doi.org/10.1038/nature22316