Large-scale oil spills cause severe ecological and economic damage. To efficiently clean up the oil, it is often adsorbed on hydrophobic materials to create a semisolid that is easier to handle than liquid oil. Polymer fibers are one suitable material for this application due to their low cost, simple production, large surface area, and hydrophobicity. Such fibers can be produced by electrospinning, however, they generally require further treatment, which hampers mass production.

Po-Yu Chen and Shih-Huang Tung, National Taiwan University, Taipei, have developed a one-step electrospinning process that produces polystyrene fibers with suitable properties for oil adsorption. The team dissolved polystyrene (PS) in a mixture of chlorobenzene and dimethyl sulfoxide (DMSO) and used electrospinning to create fibers from the resulting solution. Chlorobenzene is a good solvent for PS and DMSO is a nonsolvent, which causes a phase separation effect during drying and results in a porous structure of the produced fibers.The team was able to tune the fibers’ structure by varing the ratio of chlorobenzene and DMSO.

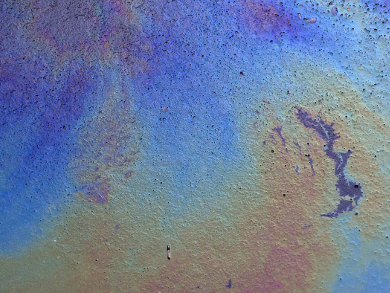

The electrospun fibers can form superhydrophobic mats, which adsorb oil selectively and rapidly while repelling water. The porous fibers show greatly increased oil adsorption capacities compared with pore-free reference fibers. According to the researchers, the approach could be used to make highly efficient sorbents for removing oil from water after spill accidents.

- One-Step Electrospinning To Produce Nonsolvent-Induced Macroporous Fibers with Ultrahigh Oil Adsorption Capability,

Po-Yu Chen, Shih-Huang Tung,

Macromolecules 2017.

DOI: 10.1021/acs.macromol.6b02696