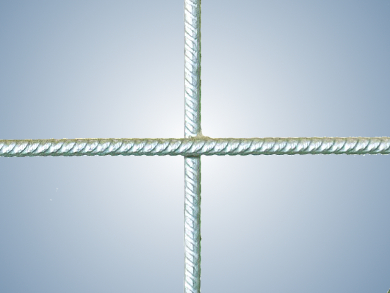

Silver nanowire films can be used as flexible transparent electrodes. The junctions between the wires are the limiting factor for the performance of such electrodes. Nanowelding of the wires to enlarge the contact surface can lower the electrical resistance of the films. However, the methods used for this, such as heating, pressure, or soldering, can be difficult to control or may change the structure of the films.

Chuan Fei Guo, Southern University of Science & Technology, Guangdong, China, Zhifeng Ren, University of Houston, TX, USA, and colleagues have developed a cold-welding process for silver nanowires that only uses water. The team prepared nanowire films and treated them with water vapor by breathing on them or with water mist from a humidifier. The water forms a thin layer between the wire junctions, and the capillary force creates enough pressure to push the wires together, weld them, and enlarge their contact surface. Because the moisture evaporates quickly, the process has to be repeated several times for an effective welding result.

The welded films showed improved conductance and mechanical stability, but remain transparent. According to the researchers, this simple process could also be used to repair damaged electrodes, to weld other metal nanowires, or to create other nanostructures.

- Capillary-Force-Induced Cold Welding in Silver-Nanowire-Based Flexible Transparent Electrodes,

Yuan Liu, Jianming Zhang, Heng Gao, Yan Wang, Qingxian Liu, Siya Huang, Chuan Fei Guo, Zhifeng Ren,

Nano Lett. 2017.

DOI: 10.1021/acs.nanolett.6b04613

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)