Redox flow batteries (RFTs) are promising candidates for energy storage systems to store wind, solar and water energy when it is available but not consumed. Anode and cathode materials are electrochemically active molecules in liquid solutions. They are stored in separate tanks and pumped through an electrochemical cell consisting of two half-cells separated by a membrane. The design of the electrochemical cell has not been studied much yet. Ulrich S. Schubert and colleagues, Friedrich Schiller University Jena, Germany, developed a tubular cell design concept which, for the first time, uses ceramic membranes.

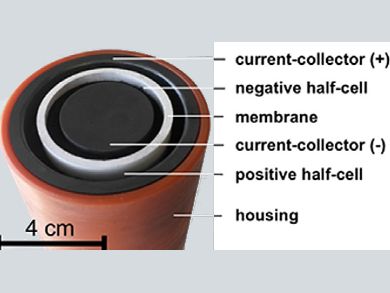

The tubular cell consists of concentric cylinders (pictured). At the interior, a graphite rod is used as current collector for the inner half-cell. It is surrounded by a graphite felt, the porous electrode, and the tubular ceramic membrane. The membrane consists of an Al2O3 substrate with open porosity. It has a ZrO2 layer on its exterior face which is the actual membrane layer and works as a size-exclusion membrane. The outer half-cell contains an identical graphite felt surrounding the membrane. A graphite tube is used as current collector. Everything is encapsulated by a PVC tube. Circular caps are glued on the top and bottom of the cell with silicone to seal it. Two syringe needles for each half-cell are integrated into the caps. They form the inlet and outlet for the electrolytes. Copper wire coiled around the inner graphite rod and outer graphite tube connects the cell to the electrochemical setup.

The internal Ohmic resistance of a laboratory prototype was investigated via electrochemical impedance spectroscopy (EIS). It showed rather high resistance (50 Ω cm2) attributed to the thickness and low porosity of the Al2O3 substrate of the ceramic membrane. Charging and discharging experiments at 100 mA over 25 cycles in a static and two cycles in a pumped operation mode successfully verified the general viability of the design.

The team expects to improve the performance of the cell by optimizing the contact between electrically conductive parts such as the felts, current collectors, copper wires, as well as the sealing, and the choice of specific graphite materials. According to the researchers, the chemical, thermal, and mechanical stability of ceramic materials and the simple scalability of tubular cells (by the length of the cell) promise new opportunities in the technological development of RFBs.

- A Tubular Polymer Redox Flow Battery with a Ceramic Membrane,

Christian Stolze, Christoph Schmerbauch, Christian Friebe, Ulrich S. Schubert,

Energy Technol. 2017.

DOI: 10.1002/ente.201600304