Carbon nanofibers (CNFs) have unique properties, such as mechanical strength, low density, and electrical conductivity, and have a range of possible applications, e.g., in the aerospace technology or in catalysis. CNFs are commonly produced by heat treatment of fibrous polymers, most often poly(acrylonitrile). However, this polymer is expensive, which causes high manufacturing costs for CNFs.

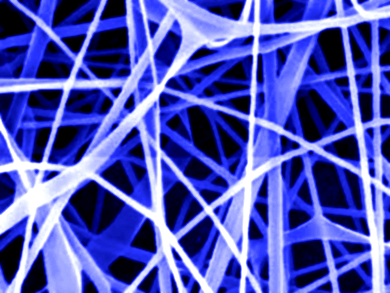

Efstratios Svinterikos and Ioannis Zuburtikudis, United Arab Emirates University, Al Ain, have developed a synthesis of CNFs which uses lignin, a renewable bioresource, and recycled poly(ethylene terephthalate) (PET), a polymer commonly used in consumer products. The team used electrospinning of a lignin/PET blend to produce polymer precursor fibers with diameters of 191 ± 60 nm, confirmed by scanning electron microscopy (SEM). Electrospinning uses an electric field between a spray nozzle and a collector plate to produce thin fibers from polymer melts or solutions. The researchers oxidized the fiber samples at 200 to 300 °C and carbonized them under an inert atmosphere at 600 °C to give CNFs.

The resulting nanofibers have a carbon content of 94.3 %. According to the researchers, their small diameter and high surface area should make them suitable as a reinforcing material, e.g., in automotive, aerospace, or construction applications, as well as for other applications, such as in separation technology or energy storage devices.

- Carbon nanofibers from renewable bioresources (lignin) and a recycled commodity polymer [poly(ethylene terephthalate)],

Efstratios Svinterikos, Ioannis Zuburtikudis,

J. Appl. Polym. Sci. 2016.

DOI: 10.1002/app.43936