Lanxess has installed an additional crystallizer at its Leverkusen site to increased its dichlorobenzene capacity by more than 15 %. Some €3 million has been invested in the capacity expansion.

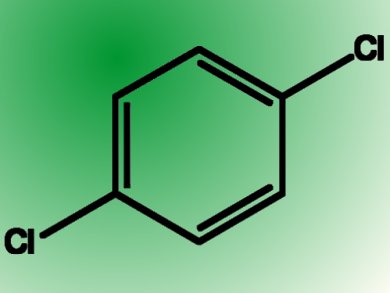

Toluene and benzene are converted into chloroaromatics by adding chlorine. In addition to low chlorinated aromatics such as monochlorobenzene, this process also produces higher chlorinated aromatics such as dichlorobenzene (DCB). DCB production involves high-purity isolation of the isomer p-dichlorobenzene (p-DCB) from a melt in a crystallization process downstream of distillation based on cooling and solidification that takes place in crystallizers.

p-DCB obtained is used to produce the high-performance semi-crystalline plastic polyphenylene sulfide (PPS). This features excellent mechanical properties, resistance to chemicals, temperature resistance, and flame retardance. PPS has applications in the electrical/electronics, automotive and aviation industries.

Another isomer that occurs during dichlorobenzene production is o-dichlorobenzene (o-DCB). Downstream processes at Lanxess use this to produce high-grade monoisocyanates for the production of crop protection agents for the global agricultural market.

- Lanxess AG, Leverkusen, Germany