A practical hydrogen storage material for fuel-cell-powered cars would need to hold at least 6 wt % of H2 to enable the car to travel a few hundred kilometers—the minimum distance needed between fill-ups. Additionally, it should be able to be charged safely with hydrogen in the same amount of time it takes to fill a car with gasoline.

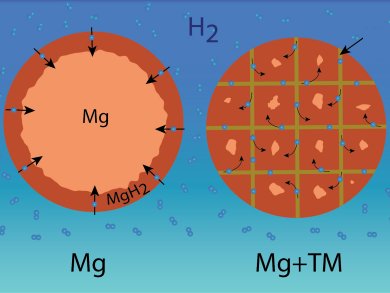

Leonid Bendersky and co-workers, National Institute of Standards and Technology (NIST), Maryland, USA, have developed thin films of magnesium powder grains doped with iron. The iron forms a network of capillaries that facilitate H2 transport within the metal grains. The films can rapidly and reversibly absorb up to 7 wt % of hydrogen and can be saturated within 60 s at 150 °C and at relatively low pressures.

This makes them a practical and safe material for hydrogen storage applications.

Image: © National Institute of Standards and Technology

- Thermodynamics, kinetics and microstructural evolution during hydrogenation of iron-doped magnesium this films

Z. Tan, C. Chiu, E.J. Heilweil, L.A. Bendersky,

Int. J. Hydrogen Energy 2011, 36, 9702-9713.

DOI: 10.1016/j.ijhydene.2011.04.196