Increasing worldwide production and consumption of plastics result in increasing public health risks, emission of hundreds of millions of tons of CO2 and consumption of petroleum. Petro-plastics are not usually made for long term usage and are not biodegradable by microorganisms. Therefore, they are an environmental burden and even also sometimes harmful for terrestrial and sea animals.

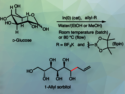

Plastics completely made from biological sources including starch, cellulose and proteins can all be consumed by microorganisms. They can be processed into environmentally friendly materials for various applications despite their various poor properties. Many biological metabolic compounds and their derivatives are useful as monomers for plastic polymers including:

- hydroxyalkanoic acids (with many structural variations),

- D- and L-lactic acid,

- succinic acid,

- bio-1,4-butanediol,

- (R)-3-hydroxypropionic acid,

- bio-ethylene (from dehydrolyzation of bio-ethanol),

- 1,3-propanediol,

- bio-propylene (from bio-isobutanol), and

- bio-ethylene glycol (from bio-ethylene) or even CO2.

Plastics produced by these monomers include:

- polyhydroxyalkanoates (PHA),

- polylactic acid (PLA),

- poly(butylene succinate) (PBS),

- polyethylene (PE),

- poly(trimethylene terephthalate) (PTT),

- polypropylene (PPP),

- polyethylene terephthalate (PET), and

- poly(propylene carbonate) (PPC).

Except bio-based PE, PP, PTT and PET, all other bio-based polymers are biodegradable at different levels. They have been proposed as sustainable, environmentally friendly, less petroleum dependent and CO2 reducing bioplastics for future applications.

Over the past 20 years, commercialization efforts have been achieved. Bio-based plastics including biodegradable PHA, PLA, PBS, PPC and non-biodegradable PE, PTT are now available in large quantities to develop applications.

These plastic polymers are normally produced by the combination of biological transformation and chemical synthesis with the only exception of PHA that are completely synthesized by microorganisms in an aqueous environment. These bio-based plastics have been studied by organic chemists, polymer scientists and engineers for their methods of polymerization, their different properties and applications. There are many possibilities to copolymerize these bio-monomers with existing petro-monomers for forming new bio-based plastics with new properties and different applications. It has become a good example of cross-disciplinary investigations.

In the current issue of Biotechnology Journal spotlights on this topic are given to reviews by Xuesi Chen, Chinese Academy of Sciences, Changchun, China, Dehua Liu, Tsinghua University, Beijing, China, and Jun Xu, Tsinghua University, Beijing, China, presenting recent developments of PLA, 1,3-propane diol, succinic acid and their copolymers and carbon dioxide-based copolymers, respectively.

- Biotechnol. J. 2010, 11.

Focus: Biopolymers - Interview with Frantisek Svec, Lawrence Berkeley National Laboratory, CA, USA:

It’s A Lot Of Plastic That Has To Be Produced!