Conducting polymers such as poly(3,4-ethylenedioxythiophene) polystyrenesulfonate (PEDOT:PSS) can combine electrical properties that are similar to those of metals or semiconductors, while retaining some of the advantages of polymers such as good mechanical properties and ease of processing. PEDOT:PSS, for example, provides mechanical flexibility, transparency, good water dispersibility, good electrical conductivity, and simple manufacturing. Developing a PEDOT:PSS formulation that can be used in 3D printing could be useful for generating complex structures. Adding polyethylene oxide (PEO) to PEDOT:PSS can increase its viscosity, which is useful for 3D printing, and improve its electrical conductivity.

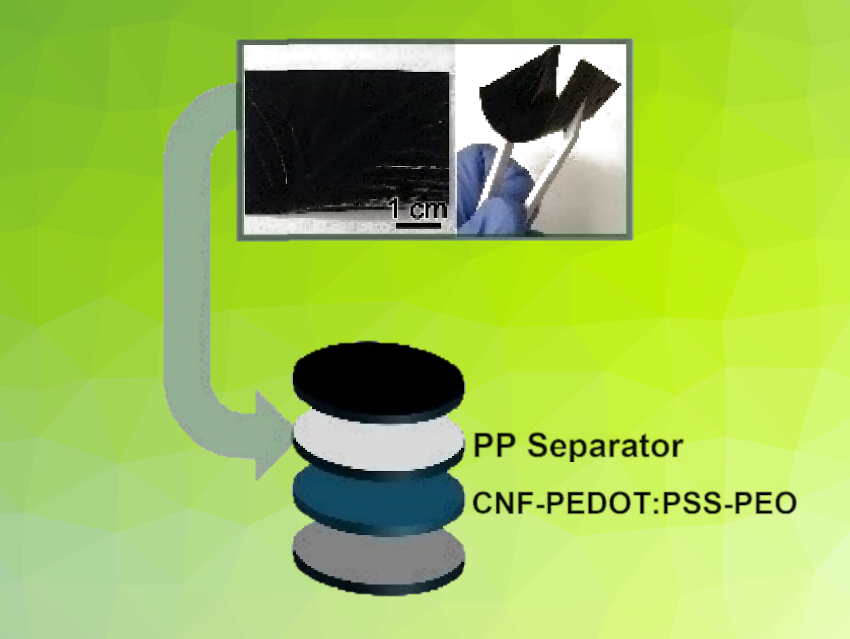

Alexander L. Yarin, Reza Shahbazian-Yassar, University of Illinois at Chicago, USA, and colleagues have developed a composite film composed of PEDOT:PSS and PEO that was 3D printed onto a carbon nanofiber substrate and used as a protective layer between a polypropylene (PP) separator and the lithium anode in lithium-ion batteries. This added layer improved the batteries’ cycling performance, mechanical properties, and thermal stability.

The team first prepared a carbon nanofiber substrate by electrospinning a polyacrylonitrile (PAN) solution, followed by carbonization of the polymer fibers. They then mixed a 3D printing ink composed of PEDOT:PSS, PEO, lithium bis(trifluoromethanesulfonyl)imide (LiTFSI), and water. The PEDOT:PSS-PEO-based ink was then printed onto a carbon nanofiber substrate via direct ink writing to form a thin CNF-PEDOT:PSS-PEO film.

The resulting composite film showed mechanical toughness, especially towards deformation. It provides better thermal stability and fire-resistant properties compared with the PP separator alone. Upon heating, the PP alone started to deform around 95 °C, while the CNF-PEDOT:PSS-PEO film began to deform at 188 °C. When the composite was used in addition to the PP separator in a lithium-ion cell, a 7.9 % increase in the long-term cycling capacity was observed. Overall, the work could be useful for the development of thin films that improve the thermal safety and cycling life of lithium-ion batteries.

- Composite PEDOT:PSS‐PEO Layers for Improving Lithium Batteries,

Timothy G. Ritter, Yong Il Kim, Breno Bezerra De Souza, Xinnian Wang, Yayue Pan, Vitaliy Yurkiv, Alexander L. Yarin, Reza Shahbazian‐Yassar,

ChemElectroChem 2024.

https://doi.org/10.1002/celc.202400458