A team led by Cristina Giordano, Max Planck Institute for Colloids and Interfaces, Germany, and the National Institute for Materials Science, Japan, have shown how mesostructured graphene nanostructures can be formed by printing an iron catalyst onto paper with an ink-jet printer and subsequent calcination of the sheets. The researchers also showed that microelectrodes could be prepared from these structures by depositing copper onto them.

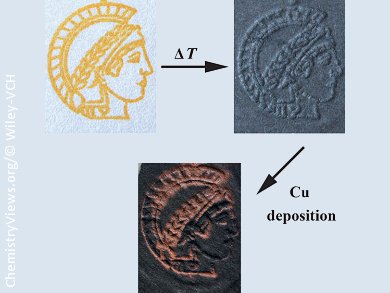

The procedure starts by filling an empty ink cartridge with an aqueous solution of iron(III) nitrate. This was printed onto a piece of pure cellulose paper. The printed paper was then heated to 800 °C under a flow of nitrogen. After heating, the printed areas turned into iron carbide nanoparticles encapsulated with a multilayer graphitic carbon shell, as well as graphene sheets. The printed areas also showed a higher electrical conductivity than the nonprinted areas, and thus copper could be selectively electrodeposited on the 2D pattern.

A variety of techniques were used to show that the reaction proceeds by the formation of liquid eutectic “droplets” that dissolve the amorphous carbon formed from cellulose and leave behind crystallized graphitic carbon.

The researchers point out that their system is cheap and fast, and can be applied to structured catalytic arrays and paper-based electronics.

- From Paper to Structured Carbon Electrodes by Inkjet Printing,

Stefan Glatzel, Zoë Schnepp, Cristina Giordano,

Angew. Chem. Int. Ed. 2013.

DOI: 10.1002/anie.201207693